What is the Supply Chain of a Company?

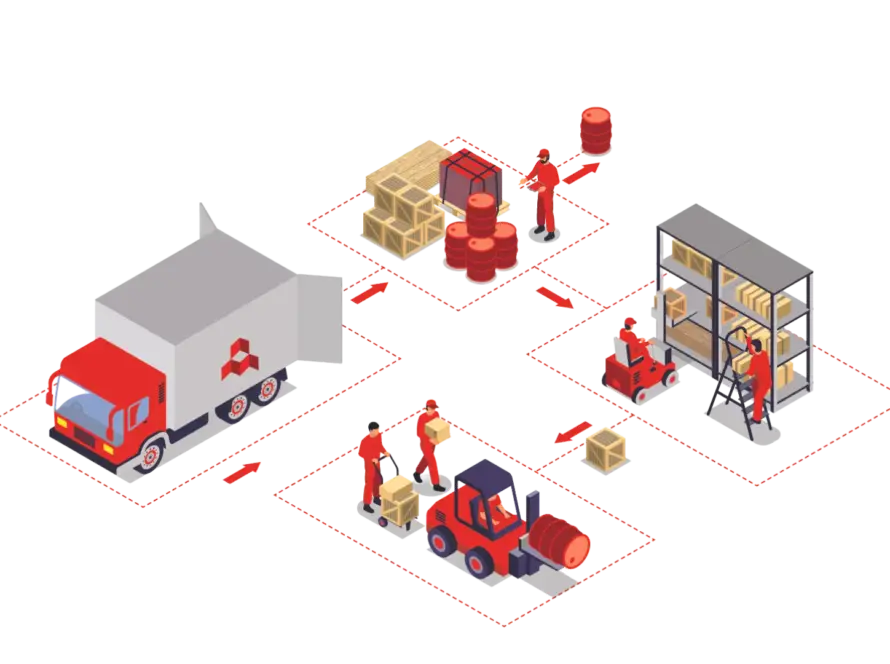

The term “supply chain” describes the interconnected web of manufacturers, distributors, and retailers that brings a finished product to market. The production of the raw materials is the first link in the chain, and the last link is the delivery of the completed product by van to the customer.

The supply chain of a company is essential since a well-oiled machine has a shorter production cycle and reduced expenses. Therefore, organizations work to enhance their supply networks to save costs and maintain competitiveness.

You May Also Like to Read: The power of supply chain optimization

Acquiring An Awareness Of The Supply Chain

Everything from the first idea to the final product or service delivery to the consumer is part of the supply chain. For example, it might begin with acquiring raw materials, then continue processing and assembly, and finally end with shipping the completed goods to a warehouse or retail location for final delivery to the customer.

Manufacturers, suppliers, wholesalers, logistics providers, retailers, and consumers are all links in the supply chain of a company.

When a company gets an order from a client, the production chain starts turning. This means that its core competencies include, among other things, the creation of new products, advertising those products, running distribution channels, handling finances, and providing support to customers.

Supplementing supply chain management may help businesses save money and increase their bottom line. In a chain, the failure of even a single link may have far-reaching and expensive consequences.

Which Supply Chain Models Are Most Common?

There are a wide variety of supply chain models to choose from. The organization’s structure and unique requirements will determine the model that best fits its situation. Several instances are listed below:

-

- Traditional businesses that mass-produce identical goods benefit from the Continuous Flow Model of supply chain management. Products should sell well and need minor tweaking. The absence of variation allows managers to stabilize production schedules and maintain strict inventory management. Managers in a continuous flow model need to restock supplies often to avoid interruptions in output.

-

- The Fast Chain Model is ideal for businesses that market items at the forefront of cultural trends. Companies following this approach must rush their wares to market if they want to cash in on the current fashion. Quick iteration is essential at each stage, from concept to prototype to final product to satisfied customer. The fast fashion sector is an industry that takes advantage of this supply chain strategy.

-

- Adaptable Business Strategy: This strategy is often used by companies that produce seasonal or holiday items. The demand for their goods spikes and then drops dramatically, creating a roller coaster of activity for these businesses. They can swiftly ramp up production because of the model’s adaptability and smoothly wind down when demand drops. They need to accurately predict their demand for raw resources, inventories, and labor if they want to turn a profit.

Exactly What Are The Top Methods For Managing A Company’s Supply Chain?

Among the characteristics of effective supply chain management systems are the following:

They have metrics that enable workers to assess the success or failure of each stage in the supply chain; they promote cooperation among the different firms in the supply chain; they seek new technologies that enhance their operations, and they support continuous development.

In Comparison To Business Logistics Management, What Is Supply Chain Management Or Supply Chain Of A Company?

Logistics commonly refers to supply chain management (SCM) and commercial logistics management. On the other hand, logistics constitute a single part of the whole supply chain.

Logistics is the study and practice of organizing and managing the flow of resources (goods and services) from their place of origin to their ultimate destination.

If you want your goods and services delivered on time and in perfect shape, you need to have a logistics plan in place that is well-managed. That positively impacts the bottom line since it reduces the amount of money the business has to spend.

You May Also Like to Read: What is Supply Chain Visibility?

Where Do Manufacturing Expenses Go, And Why?

Effective supply chain management ensures that all product components are available at the right time and place. In addition, maintaining a steady rate of production expenses is essential.

Companies making goods that use components from various suppliers should pay special attention to the dynamics of their production costs. For example, to make garments, a factory may need a timely supply of several features, such as fabric, zippers, trim, and thread. Too early delivery of goods may necessitate the company’s spending money on storage. Conversely, if some people are late, the equipment will sit idle.

The Importance Of Dependable Vendors

Having trustworthy vendors is essential for effective supply chain management. This implies that they make and ship a quality product on a schedule that conforms to the original equipment manufacturer’s requirements.

Let’s pretend for a moment that XYZ Furniture is a luxury furniture manufacturer that relies on a supplier for metal handles and other hardware. The metal parts must have a high level of durability for them to survive for decades. They need to be of the quality and function as the manufacturer intended.

A trustworthy vendor will fulfill the order and promptly dispatch the components.

What Role Does The Supply Chain Play In Deflation?

Reduced price increases may be attributed mainly to the improved performance of supply networks. Costs associated with transporting goods reduce as distribution efficiency improves, ultimately benefiting the customer. While deflation has a bad reputation, it can improve supply chain efficiency in certain situations.

Globalization has led to more significant supply chain optimization, maintaining downward pressure on input costs.

What Is The Progressive Process Of Supply Chain Of A Company?

Experts agree on five features that make up effective supply chain management systems:

-

- Planning

To satisfy client demand, businesses must carefully plan and manage their supply chains. Once the supply chain is in place, KPIs should be set to assess whether it is successful, efficient, providing value to customers, and in line with the company’s overall objectives.

-

- Sourcing

Select vendors to provide materials and services for manufacturing. Set up systems to monitor and control your vendors after that. The crucial procedures are ordering, receiving, inventory management, and paying suppliers.

-

- Manufacturing

Schedule and manage the processes needed to take raw materials, produce the product, evaluate its quality, package it for shipment, and deliver it.

-

- Transport and Distribution

Manage orders, coordinate shipping, distribute loads, bill, and collect from clients.

-

- · Returning

Make arrangements for the return of unwanted or unused goods.

You May Also Like to Read: What is Supplier Relationship Management (SRM)?

The Conclusion

Navata SCS is an ideal platform for the supply chain of a company needs. You may get in touch with their experts to get the right solutions as per your business model. From transportation to warehouse management to supply chain solutions will be provided to you hassle-free. So, what are you waiting for book a consultation now!

7 Comments