Agentic AI in Logistics: The New Engine

Logistics and supply chains are entering a phase where efficiency is no longer enough. Markets move faster, customers expect instant delivery, disruptions hit without warning, and traditional automation—RPA, rule engines, BI dashboards—cannot keep up.

This is where Agentic AI becomes a breakthrough.

Instead of simply predicting or recommending, Agentic AI in logistics can actually act, plan, and self-orchestrate end-to-end operations. It behaves like a digital workforce of autonomous agents capable of coordinating fleets, optimizing warehouses, managing orders, avoiding disruptions, and stabilizing supply chain flows in real time.

In other words:

- Traditional AI automates tasks.

- Agentic AI automates decisions and actions.

And that shift is redefining logistics performance, cost structures, and delivery reliability at scale.

Read More About:| The Role of Artificial Intelligence in Supply Chain Optimization

What Is Agentic AI in Logistics?

Agentic AI refers to AI systems built from multiple intelligent agents that can independently analyze situations, make decisions, and take actions inside complex operational environments like supply chains, warehouses, and transport networks.

Each “agent” behaves like a specialized digital operator—one may manage fleet routing, another may handle inventory balancing, another may solve delivery exceptions.

Together, they create a self-driving supply chain layer that continuously optimizes the movement of goods, people, and resources.

Core capabilities of Agentic AI in logistics include:

Autonomous fleet and route optimization

End-to-end order fulfillment orchestration

Predictive and adaptive warehouse management

Real-time disruption mitigation

Dynamic transportation planning

Multi-agent coordination across nodes

Self-improving workflows and automated decision loops

This transforms the supply chain from reactive to predictive, proactive, and self-correcting.

Importance of Agentic AI

Global supply chains have become too complex for humans and rules-based systems to manage manually:

Volatile demand patterns

Driver shortages

Faster SLAs and same-day delivery growth

Increasing compliance and documentation requirements

Real-time visibility expectations

Cost pressure from fuel, labor, fleet maintenance

Weather disruptions and geopolitical uncertainty

Legacy systems struggle because they still require humans to interpret data and take action.

Agentic AI removes this bottleneck.

It gives logistics companies something they’ve never had before: autonomous decisioning at scale.

How Agentic AI Works Inside Logistics Operations

Below is a practical, high-depth view of how agent-based AI systems transform everyday logistics functions.

1. Autonomous Fleet & Route Optimization

Instead of dispatch teams building routes, Agentic AI agents:

Study real-time traffic

Predict congestion

Evaluate fuel consumption

Analyze vehicle conditions

Consider customer SLAs

Balance workloads across drivers and hubs

Then they generate and execute the optimal plan, adjusting every few minutes as conditions change.

This reduces fuel spend, improves ETAs, and dramatically boosts delivery consistency.

2. Intelligent Warehousing & Inventory Flow Control

Agentic AI inside warehouses acts like a 24/7 digital supervisor.

It:

Predicts demand surges

Optimizes pick–pack–ship workflows

Prioritizes urgent orders

Auto-assigns tasks to workers or robots

Balances load across zones

Prevents bottlenecks before they occur

It also synchronizes inventory across eCommerce, retail, and B2B channels, ensuring real-time accuracy.

3. Self-Healing Supply Chain Operations

In traditional workflows, when exceptions happen—vehicle breakdowns, address issues, inventory mismatches—teams scramble to fix them.

Agentic AI does the opposite.

It detects issues early, diagnoses the root cause, chooses the best response, and takes corrective action automatically:

Reroutes deliveries

Replaces vehicles

Reassigns drivers

Updates customer ETAs

Adjusts warehouse picking priorities

Balances inventory across hubs

This keeps fulfillment smooth even when disruptions strike.

4. Dynamic Workforce & Asset Allocation

Agentic AI continuously optimizes how people and assets are deployed:

Reassigns drivers based on workload

Suggests labor shifts inside warehouses

Improves dock scheduling

Plans maintenance windows

Reduces empty miles and idle time

Every resource becomes more productive without overworking the workforce.

5. Autonomous Decision Loops Across the Entire Value Chain

The biggest advantage of Agentic AI is closed-loop automation:

Sense → Analyze → Decide → Act → Learn → Improve

This eliminates human dependency for repetitive decisioning and creates a self-improving engine for logistics performance.

Keywords integrated: closed-loop automation, self-orchestrating supply chain systems, intelligent logistics automation.

Benefits of Agentic AI for Logistics & Supply Chains

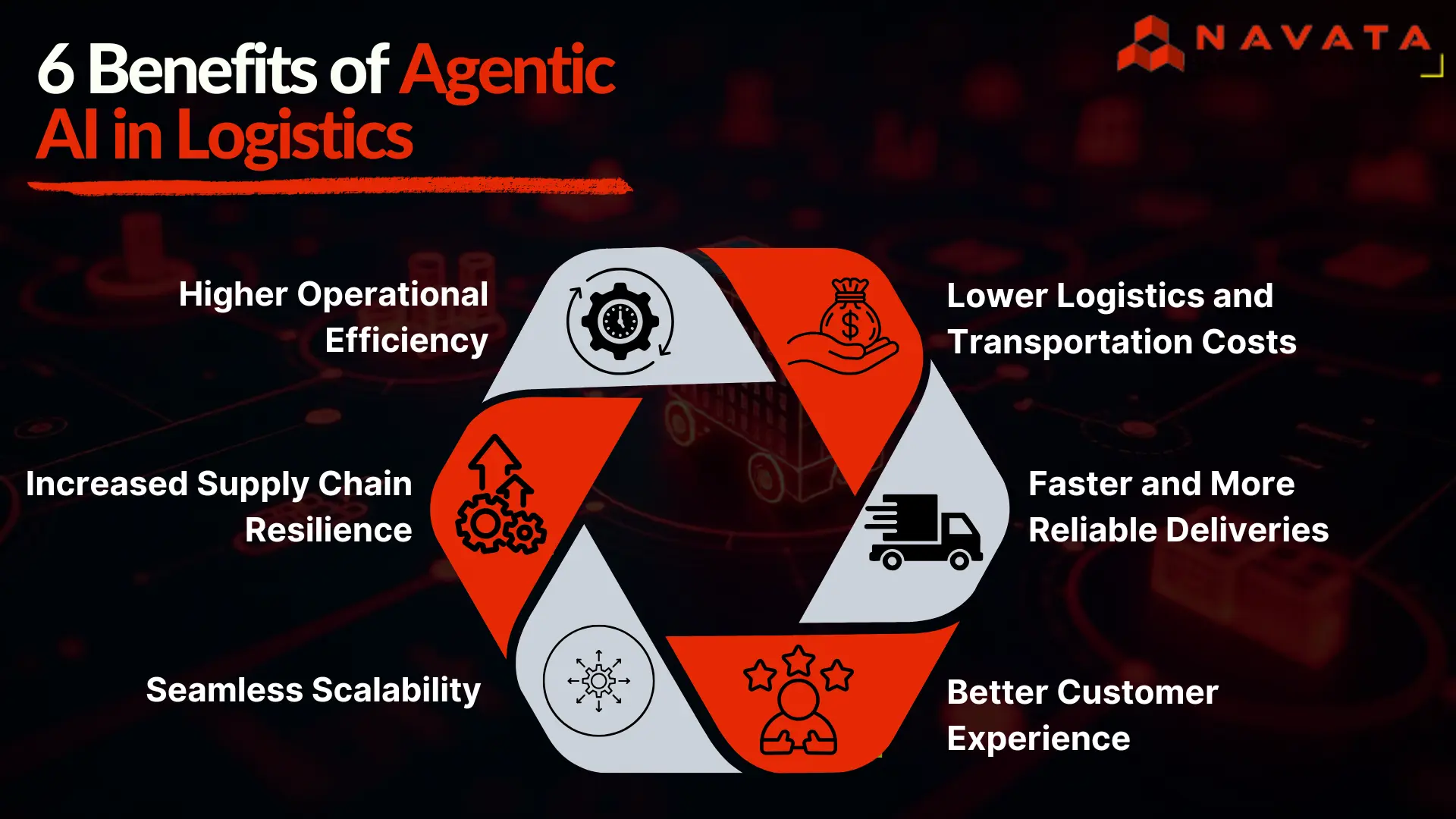

1. Higher Operational Efficiency

Agentic AI automates daily logistics decisions—from routing to warehouse task allocation—eliminating manual coordination and reducing process delays. By constantly optimizing workflows in real time, it increases throughput, reduces idle time, and ensures every resource operates at peak efficiency. This creates a faster, leaner, and more synchronized supply chain.

2. Lower Logistics and Transportation Costs

With autonomous routing, demand forecasting, and predictive maintenance, Agentic AI directly reduces fuel expenses, labor inefficiencies, empty miles, and vehicle downtime. It minimizes waste across fleet and warehouse operations, resulting in substantial cost savings. Businesses gain tighter cost control and improved margins without compromising service levels.

3. Faster and More Reliable Deliveries

Agentic AI continuously reacts to real-time conditions—traffic, delays, inventory gaps—and autonomously adjusts routes, tasks, and priorities. This ensures tighter SLA adherence, quicker issue resolution, and highly accurate ETAs. Deliveries become faster, more predictable, and more resilient to variability across first-mile, mid-mile, and last-mile operations.

4. Better Customer Experience

Customers benefit from accurate ETAs, proactive notifications, and fewer delays. Agentic AI ensures smoother fulfillment by predicting issues early and reassigning resources instantly. This reduces failed deliveries, enhances transparency, and creates a more reliable post-purchase experience. Over time, brands see stronger customer trust and higher repeat orders.

5. Seamless Scalability

As order volumes grow, Agentic AI automatically scales operational capacity without requiring more planning staff or larger control rooms. It rebalances workloads across fleets, warehouses, and delivery hubs to handle demand spikes effortlessly. This software-driven scalability is ideal for fast-growing eCommerce, retail, and 3PL logistics networks.

6. Increased Supply Chain Resilience

Agentic AI anticipates disruptions—weather events, congestion, demand shifts, supplier delays—and autonomously takes preventive action. By analyzing risks ahead of time and adjusting plans instantly, it keeps operations running smoothly even in volatile conditions. This improves service reliability and protects businesses from costly operational breakdowns.

You May Also Like to Read: Role of Artificial Intelligence and Machine Learning in Supply Chain

Where Agentic AI Will Have the Biggest Impact

Here are the highest-impact use cases already gaining traction:

Urban last-mile delivery networks

Fleet and fuel optimization for transporters

Quick commerce dark store orchestration

Predictive warehouse automation

International freight coordination

Cold-chain logistics stability

B2B manufacturing supply chains

High-volume eCommerce fulfillment

Companies that adopt Agentic AI early will shape the next generation of logistics performance.

Conclusion

Agentic AI is rapidly evolving into the core operating system of modern logistics—moving the industry from simple automation to truly autonomous, self-optimizing systems. Instead of merely supporting human teams, it becomes a digital command layer that drives faster decisions, reduces operational costs, enhances accuracy, and adapts in real time to disruptions.

As logistics competition increasingly depends on speed, predictability, and efficiency, Agentic AI will define the next generation of high-performance supply chains. The question now isn’t whether companies will adopt it, but how quickly they can transition to fully autonomous logistics to stay competitive.

Thanks For Reading: Agentic AI in Logistics: The 2026 Guide to Autonomous Supply Chains

Powered By 360Presence