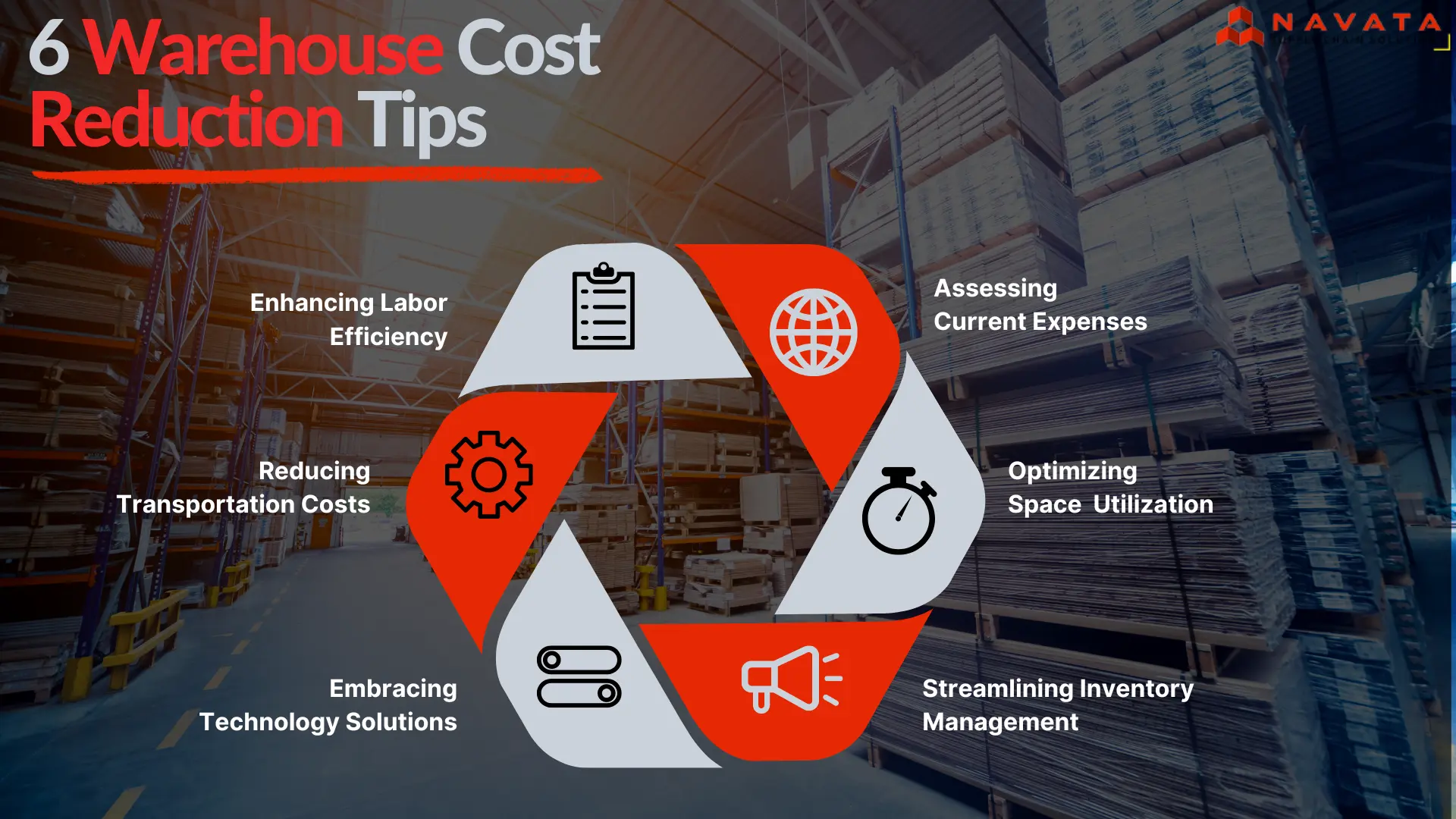

6 Warehouse Cost Reduction Tips

Reducing warehouse costs is crucial for optimizing business operations and boosting profitability. Warehousing expenses often constitute a significant portion of operational costs for many businesses, especially those involved in manufacturing, distribution, or retail.

Effective management of warehouse expenses not only directly impacts the bottom line but also plays a pivotal role in streamlining processes and meeting customer demands. Here’s why:

Importance of Warehouse Management

Cost Optimization: Warehousing expenses can constitute a significant portion of a company’s operational costs. By reducing these costs through efficient management practices, businesses can improve their overall financial health and allocate resources more strategically to fuel growth and innovation.

Streamlined Processes: A well-managed warehouse ensures smooth and efficient operations, from receiving and storing inventory to picking, packing, and shipping orders. By optimizing processes and workflows, businesses can minimize delays, errors, and bottlenecks, thereby enhancing productivity and maximizing throughput.

Meeting Customer Demands: In today’s fast-paced market environment, customers expect timely and accurate order fulfillment. Efficient warehouse management enables businesses to meet these demands by ensuring that the right products are available when and where they are needed. This leads to improved customer satisfaction, loyalty, and repeat business.

Competitive Advantage: Businesses that excel in warehouse management gain a competitive edge by offering superior service levels, faster delivery times, and lower operating costs. This positions them as preferred partners for suppliers and customers alike, driving growth opportunities and market expansion.

Looking to streamline your warehouse operations and reduce costs? Here are six practical tips and techniques to help optimize your processes and improve efficiency:

Assessing Current Expenses

Analyzing existing costs associated with warehouse operations is crucial for identifying areas where expenses can be reduced. This includes scrutinizing expenses such as rent, utilities, labor, equipment maintenance, and inventory management. By leveraging financial data and performance metrics, businesses can pinpoint areas of overspending or inefficiency. This comprehensive assessment provides a clear understanding of where cost-saving initiatives should be focused, laying the groundwork for strategic optimization efforts.

Optimizing Space Utilization

Efficient space utilization is essential for maximizing the capacity of the warehouse while minimizing costs. Techniques such as vertical storage, well-planned aisle layouts, and organized inventory management systems can significantly enhance space efficiency. Warehouse management software (WMS) plays a pivotal role in optimizing storage allocation, reducing unnecessary movements, and improving overall operational efficiency. Additionally, exploring opportunities for consolidation and reorganization enables businesses to make better use of available space, further reducing overhead costs.

Streamlining Inventory Management

Streamlining inventory management processes is vital for minimizing costs associated with excess inventory holding and stockouts. Adopting just-in-time (JIT) inventory practices helps minimize inventory levels while ensuring timely fulfillment of customer orders. Implementing demand forecasting tools enables businesses to accurately anticipate customer needs and adjust inventory levels accordingly, reducing excess inventory and associated costs. Furthermore, employing ABC analysis allows for the prioritization of inventory items based on their value and demand, optimizing resource allocation and reducing carrying costs.

You Might Also Like To Read: Advanced Warehousing Technologies: 5 Latest Trends

Enhancing Labor Efficiency

Investing in labor efficiency measures is essential for optimizing warehouse operations and reducing costs. Employee training programs can improve productivity and reduce errors, leading to streamlined processes and reduced operational costs. Implementing performance incentives and recognition programs motivates staff, fostering a culture of efficiency and accountability within the workforce. Additionally, considering automation and robotics for handling repetitive tasks can free up human resources for more strategic functions, further enhancing labor efficiency and reducing costs.

Reducing Transportation Costs

Minimizing transportation costs is critical for optimizing overall logistics expenses. Optimizing shipping and receiving schedules helps minimize transportation expenses and avoid unnecessary delays, leading to cost savings. Consolidating shipments and negotiating favorable contracts with carriers enable businesses to secure competitive rates and reduce transportation costs. Exploring alternative transportation modes and forming logistics partnerships can also provide cost-effective solutions for transporting goods, further reducing transportation expenses.

Embracing Technology Solutions

Leveraging advanced technologies is key to enhancing visibility, control, and efficiency in warehouse operations. Technologies such as RFID, IoT sensors, and predictive analytics enable businesses to track inventory in real-time, optimize workflows, and make data-driven decisions, leading to cost reductions. Implementing cloud-based warehouse management systems (WMS) and inventory tracking systems improves accuracy and efficiency in managing inventory, reducing errors and associated costs. Continuously evaluating and investing in emerging technologies ensures that businesses stay ahead of the curve, driving continuous improvement and further cost reductions.

Conclusion

In conclusion, warehouse cost reduction strategies play a pivotal role in optimizing business operations and enhancing profitability. By assessing current expenses, optimizing space utilization, streamlining inventory management, enhancing labor efficiency, reducing transportation costs, and embracing technology solutions, businesses can achieve significant cost savings while improving operational efficiency. These strategies enable businesses to meet customer demands effectively, drive continuous improvement, and maintain competitiveness in today’s dynamic business landscape.

Thanks For Reading: Warehouse Cost Reduction: 6 Practical Tips and Techniques

Powered By 360Presence

3 Comments

Stewart

You have made some good points there. I looked on the web to

learn more about the issue and found most people will go along with your views on this

web site.