What is Supply Chain Visibility?

In the contemporary world where competition is high and markets are global, supply chain management has become more important than ever. The challenges of managing the supply chain coupled with the escalating pressure to improve supply chain transparency and efficiency have made Supply Chain Visibility (SCV) an important factor in today’s business environment. But what does SCV mean and why is it so crucial in the current environment?

Supply chain visibility can be defined as the capacity to monitor every aspect of the supply chain beginning from the procurement of materials through production, distribution, and ending at the customer level. It covers all aspects of inventory management, orders, and shipments, as well as suppliers’ performance.

You May Also Like to Read: The Role of Artificial Intelligence in Supply Chain Optimization

Types of Supply Chain Visibility

Different kinds of supply chain visibility are relevant when inventory flows through the supply chain. Each type adds to a thorough grasp of the entire process by concentrating on distinct facets of the supply chain:

Order Visibility

It is the ability to follow an order’s development from the time it is placed until it is delivered. Businesses may manage consumer expectations by giving accurate delivery estimates, and handle any problems that may occur during order fulfillment by keeping an eye on order visibility.

Inventory Visibility

It is the capacity to keep an eye on stock levels at different points across the supply chain. It involves keeping tabs on inventory levels in distribution hubs, retail stores, and warehouses. Good inventory visibility lowers the risk of overstocking or stockouts, facilitates effective stock-level management, and guarantees that goods are available when and where they are needed.

Production Visibility

This refers to keeping an eye on the manufacturing process, including the state of operations and the advancement of production orders. Businesses can make sure that manufacturing operations are moving forward, spot possible bottlenecks, and improve production schedules by having visibility into production activity.

Shipment Visibility

It is the ability to follow the flow of products as they are moved across the supply chain. With real-time updates on the whereabouts and conditions of goods, cargo visibility helps companies handle transportation more efficiently and react quickly to any delays or problems that may arise.

You May Also Like to Read: Digital Transformation in Supply Chain

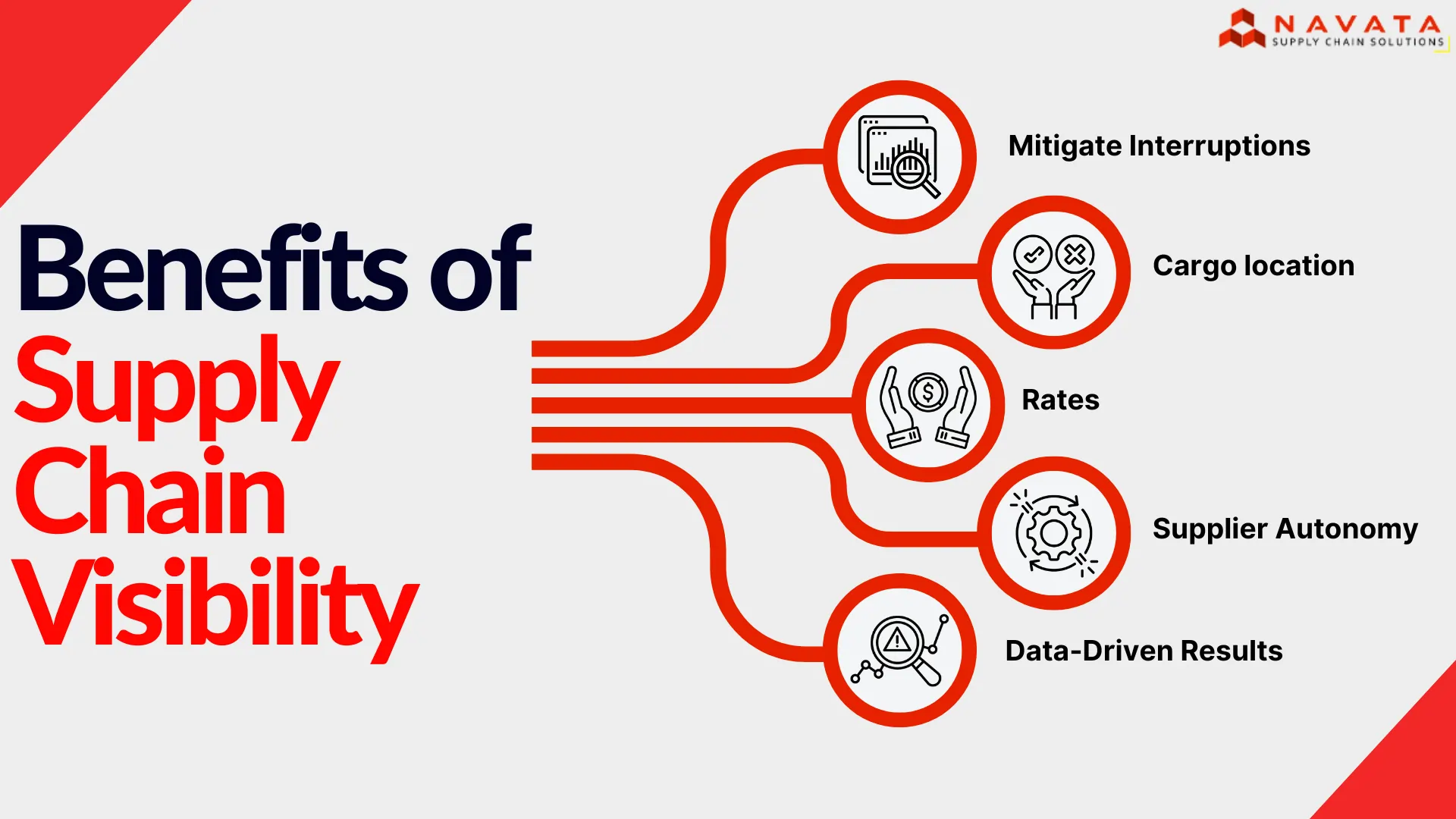

Benefits of Supply Chain Visibility

The benefits of improved supply chain visibility all contribute to better workflow and higher profits. Furthermore, improved visibility enables firms to lower customer expenses while also reducing risk. Let us look at a few more major benefits of supply chain visibility:

Mitigate interruptions

Knowing where potential disruptions may arise ahead of time reduces the likelihood that they will cause difficulties. Operating a supply chain based on robust data analysis and communication will reduce the possibility of bottlenecks while producing extraordinary results.

Cargo location

One of the most critical and foundational aspects of SCV is real-time visibility into cargo location and shipping status. Having access to the actual location of an order allows a company to plan when to repurchase and deliver supplies, remain on top of payments, and keep internal and external stakeholders up to date on the status of materials and products.

Rates

Rates are defined as the costs of transporting freight. As a result, having visibility into them allows businesses to better understand how much they are spending on moving, shipping, and delivering freight.

Supplier Autonomy

As supply chain visibility improves, so does confidence between suppliers and brands. This opens up the possibility of giving suppliers the autonomy to conduct self-inspections on a certain percentage of orders, for smaller and routine QC instances, and when a supplier has continuously exhibited high quality performance.

Data-Driven Results

Visibility into all aspects of your supply chain allows you to access large amounts of supply chain data. This data, when processed and combined with an experienced service provider helps businesses to make quick, smart data-backed decisions that will lead to greater supply chain success.

Thanks For Reading: What is Supply Chain Visibility?

Powered By 360Presence

1 Comment