Why AI-Driven Predictive Supply Chains?

Traditional supply chains react to disruptions only after they occur, causing delays, higher costs, and lost sales. An AI-driven predictive supply chain uses artificial intelligence and real-time data to forecast demand, optimize inventory, and prevent operational issues before they happen.

Companies adopting this approach improve efficiency, reduce costs, and enhance delivery reliability, turning their supply chain into a measurable business advantage.

To dive deeper into how these technologies work, explore our detailed guide on the [Role of Artificial Intelligence and Machine Learning in Supply Chain].

What is AI-Driven Predictive Supply Chain?

An AI-driven predictive supply chain integrates advanced analytics, real-time data, and intelligent automation to forecast demand, detect risks, and optimize operations proactively. Unlike reactive supply chains, which solve problems after they occur, predictive supply chains enable companies to make data-driven decisions in advance, reducing costs and improving delivery performance.

Key Benefits:

Accurate Demand Forecasting: Anticipates market trends, seasonality, and customer preferences.

Optimized Inventory Management: Maintains optimal stock levels to prevent overstocking and stockouts.

Enhanced Logistics Efficiency: AI-driven route planning reduces delivery delays and transportation costs.

Operational Resilience: Early detection of supplier, production, or transport risks allows proactive mitigation.

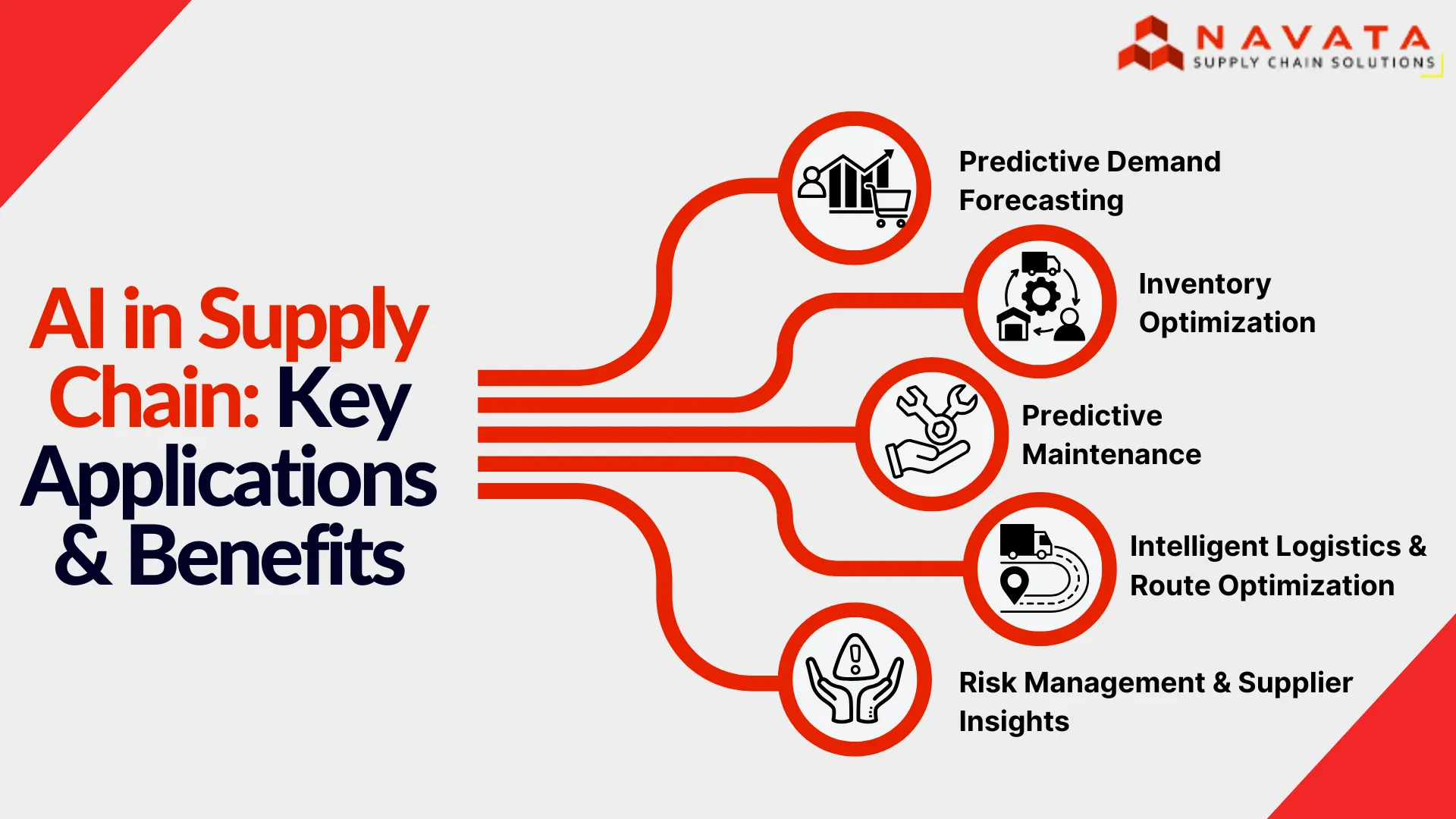

How AI is Transforming Supply Chain Operations?

AI applications are revolutionizing supply chains across industries:

- Predictive Demand Forecasting

Machine learning algorithms analyze historical sales, seasonal trends, and market conditions to forecast demand with high accuracy. Retailers and e-commerce companies reduce stockouts, improve order fulfillment, and enhance customer satisfaction. - Inventory Optimization & Dynamic Replenishment

AI continuously evaluates inventory levels, identifies fast- and slow-moving SKUs, and recommends replenishment schedules. This reduces holding costs, improves cash flow, and prevents lost sales. - Predictive Maintenance

IoT sensors and AI predict equipment failures in warehouses, transportation fleets, or production lines. Businesses can schedule maintenance proactively, minimizing downtime and reducing repair costs. - Intelligent Logistics & Route Optimization

AI calculates the fastest, most fuel-efficient delivery routes by analyzing traffic, weather, and vehicle capacity, improving on-time deliveries and reducing operational costs. - Risk Management & Supplier Insights

AI monitors suppliers, market trends, and potential disruptions, enabling companies to act before a risk impacts operations.

Real-World Impact of AI in Supply Chains

AI-driven predictive supply chains deliver measurable results:

Retail & E-commerce: Amazon and Noon use AI to forecast demand and optimize delivery routes, improving fulfillment accuracy and speed.

Manufacturing: Toyota applies predictive maintenance on assembly lines, reducing downtime and operational costs by 20–30%.

Logistics & Transportation: NSCS leverages AI for route planning and warehouse automation, reducing costs by 12–18% and enhancing delivery performance.

By adopting AI-driven predictive supply chain strategies, companies improve efficiency, resilience, and customer satisfaction, gaining a significant competitive edge.

Implementing AI-Driven Predictive Supply Chains

Transitioning to a predictive supply chain requires strategic integration of AI and organizational alignment:

Integrate Data Systems: Connect ERP, WMS, TMS, and IoT systems to provide AI with real-time actionable data.

Continuous Learning: AI models improve over time, adjusting forecasts for demand, inventory, and logistics.

Cross-Functional Collaboration: Procurement, operations, logistics, and sales teams must act on AI insights collectively.

Start with Pilot Projects: Focus on high-impact areas like inventory management or route planning before scaling across the supply chain.

The Future of Predictive Supply Chains

AI is shaping the next generation of supply chains:

Hyper-Personalization: Anticipating customer demand and adjusting inventory accordingly.

Autonomous Operations: Robotics and AI create near-autonomous warehouses and last-mile delivery solutions.

Sustainable Supply Chains: Predictive analytics optimize resource usage, reducing waste and carbon footprint.

Businesses embracing AI-driven predictive supply chains are better prepared for market volatility, operational disruptions, and evolving customer expectations, achieving long-term efficiency and growth.

Optimize Your Supply Chain with Experts!

Cut costs. Boost efficiency. Stay ahead.

Conclusion

An AI-driven predictive supply chain moves businesses from reactive problem-solving to proactive, intelligent operations. Companies leveraging predictive AI gain agility, efficiency, resilience, and strategic advantage, making predictive supply chains essential for modern supply chain success.

Thanks For Reading: AI-Driven Predictive Supply Chains: Moving Beyond Reactive Operations

Powered By 360Presence

Frequently Asked Questions (FAQs)

Q1. What is an AI-driven predictive supply chain?

An AI-driven predictive supply chain uses artificial intelligence and real-time data to forecast demand, optimize inventory, and prevent disruptions before they occur.

Q2. How does AI improve supply chain efficiency?

AI improves efficiency through predictive demand forecasting, route optimization, inventory management, and real-time risk prediction, reducing costs and improving delivery reliability.

Q3. What industries benefit most from predictive supply chain management?

Retail, eCommerce, manufacturing, healthcare, and logistics companies benefit the most, as predictive analytics help them reduce stockouts, manage risks, and improve customer satisfaction.

Q4. Is predictive supply chain management expensive to implement?

Implementation costs vary, but AI tools often deliver high ROI by reducing wastage, minimizing downtime, and improving order accuracy, making them cost-effective in the long run.

Q5. What is the future of AI in supply chain operations?

The future lies in autonomous supply chains powered by AI, machine learning, and IoT, enabling real-time decision-making, predictive risk management, and sustainable logistics practices.