Data and Analytics in Supply Chain Management

Supply chains today are complex global networks, demanding faster, more efficient, and cost-effective operations. Data and analytics in supply chain management have become crucial for optimizing these intricate systems.

This involves collecting and analyzing vast amounts of data from suppliers, manufacturers, logistics, and customers to gain supply chain visibility analytics.

By transforming raw data into actionable insights, businesses can make informed decisions and foster innovation. Advanced technologies like AI & ML in supply chain, and the Internet of Things (IoT) amplify this capability, enabling the analysis of real-time data to uncover patterns and drive efficiency.

Ultimately, data analytics is transforming how businesses navigate and succeed in the modern supply chain landscape.

You May Also Like to Read: The Role of Artificial Intelligence in Supply Chain Optimization

Why Data and Analytics Are Crucial for Supply Chains

Supply chains generate a colossal amount of data daily, encompassing everything from inventory levels and shipment tracking to supplier performance metrics and invaluable customer feedback. Without proper analysis, this wealth of information remains largely untapped and underutilized. Data analytics acts as the catalyst, converting this raw data into actionable insights that drive tangible improvements. Here’s why it’s absolutely vital:

Enhanced Visibility

Data analytics provides unparalleled end-to-end visibility by seamlessly integrating data from disparate sources. This enables businesses to track shipments in real-time, monitor inventory levels with precision, and swiftly identify potential bottlenecks in the supply chain. This is crucial for real-time supply chain data management.

Improved Decision-Making

Armed with data-driven insights, businesses can make more informed and strategic decisions. Whether it’s optimizing inventory levels to prevent stockouts, selecting the most efficient transportation routes, or choosing the most reliable and cost-effective suppliers, analytics provides the clarity needed for optimal choices.

Cost Reduction

By identifying inefficiencies and optimizing processes, data analytics directly contributes to significant supply chain cost reduction. Predictive analytics supply chain helps minimize excess inventory, and sophisticated transportation optimization data algorithms can drastically reduce transportation costs.

Increased Agility and Resilience

In today’s often unpredictable business environment, agility and resilience are paramount. Data and analytics in supply chain management empower businesses to proactively predict disruptions, meticulously assess potential risks, and implement robust contingency plans, ensuring smooth operations even in the face of unforeseen challenges. This also ties into effective supply chain risk analytics.

Customer Satisfaction

By thoroughly analyzing customer insights supply chain data, businesses can gain a deeper understanding of preferences, accurately predict demand fluctuations, and tailor their offerings to precisely meet customer expectations, thereby significantly enhancing overall customer satisfaction.

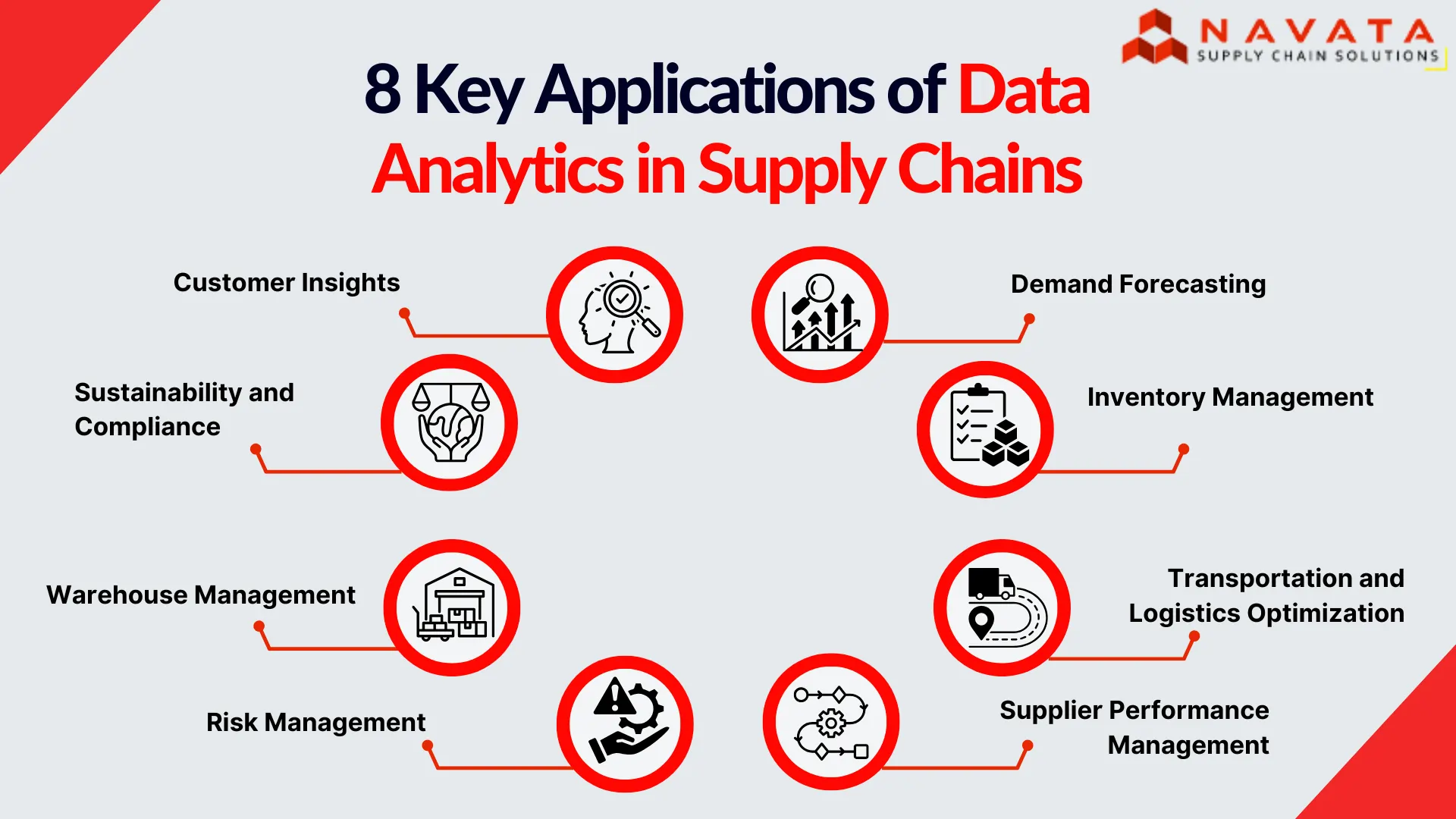

Key Applications of Data Analytics in Supply Chains

Data analytics finds extensive application across various facets of supply chain management, with some of the most impactful uses including:

1. Demand Forecasting

Accurate demand forecasting analytics is fundamental to maintaining optimal inventory levels and preventing costly stockouts or detrimental overstocking. By analyzing historical sales data, prevailing market trends, and a multitude of external factors, businesses can predict future demand with greater precision. This includes predictive analytics techniques for inventory management.

2. Inventory Management

Real-time insights into inventory levels allow businesses to meticulously track stock movements, identify slow-moving items, and determine optimal reorder points, all contributing to highly efficient inventory optimization data. This helps in optimizing inventory levels with real-time data analytics.

3. Transportation and Logistics Optimization

Transportation costs represent a significant expense in most supply chains. Data analytics in logistics optimizes route planning, facilitates efficient load consolidation, and aids in intelligent carrier selection, taking into account critical factors such as traffic patterns, fluctuating fuel costs, and precise delivery times. This also covers AI-powered route optimization for supply chains and reducing shipping delays through data-driven insights.

4. Supplier Performance Management

Analytics-driven supplier performance management in supply chains enables a comprehensive evaluation of supplier performance based on crucial metrics like on-time delivery rates, product quality, and cost efficiency. This allows businesses to mitigate risks by partnering with the most reliable and high-performing suppliers, enhancing supplier performance analytics.

5. Risk Management

Data and analytics in supply chain management help businesses proactively identify potential risks, thoroughly assess their potential impact, and formulate robust contingency plans, thereby strengthening the overall resilience of their supply chains. This specifically addresses how data analytics mitigates supply chain disruptions.

6. Warehouse Management

Within warehouses, warehouse analytics solutions optimize storage layouts, streamline picking processes, and significantly reduce inefficiencies, ultimately boosting productivity and accuracy.

7. Sustainability and Compliance

As sustainability becomes an increasingly critical focus, data analytics for sustainable supply chain management assists in monitoring environmental impact by analyzing energy consumption, carbon emissions, and waste generation, ensuring compliance with evolving regulations and fostering eco-friendly practices. This ensures sustainable supply chain data is leveraged effectively.

8. Customer Insights

By deeply understanding customer preferences and feedback, businesses can personalize offerings, significantly improve satisfaction, and cultivate enduring, long-term customer relationships.

You May Also Like to Read: What is Warehouse Management System (WMS)?

The Technologies Driving Data and Analytics in Supply Chains

The efficacy of data and analytics in supply chain management is significantly amplified by several cutting-edge technologies:

AI and Machine Learning (ML)

AI in supply chain and machine learning logistics algorithms are instrumental in analyzing vast datasets to identify intricate patterns and predict future outcomes. These technologies are widely used for sophisticated demand forecasting, proactive predictive maintenance, and highly automated decision-making processes. This includes using machine learning for accurate sales forecasting.

Internet of Things (IoT)

IoT devices, such as smart sensors and GPS trackers, provide invaluable real-time supply chain data on inventory, shipments, and equipment status, helping to optimize operations with unprecedented accuracy.

Blockchain

Blockchain supply chain data technology offers secure and transparent record-keeping, making it exceptionally useful for tracking the provenance of goods and ensuring compliance across the entire supply chain. This helps with blockchain’s role in supply chain traceability and data.

Cloud Computing

Cloud computing supply chain platforms provide the scalable infrastructure necessary for businesses to store and analyze massive datasets in real-time, facilitating seamless collaboration and data sharing throughout the supply chain.

Big Data Analytics

Big data supply chain analytics capabilities are essential for processing truly massive datasets to uncover profound trends and insights, empowering businesses to make highly informed strategic decisions. This helps with how big data enhances demand visibility.

Overcoming Challenges in Implementation

While the benefits of data analytics in supply chain are substantial, businesses often face several challenges during implementation:

Data Quality and Integration

Supply chain data is frequently fragmented and stored in disparate systems, posing a significant challenge in ensuring data quality and integrating it into a unified, coherent platform. This highlights the importance of data quality in supply chain analytics.

High Implementation Costs

Setting up comprehensive data analytics solutions typically requires substantial investment in cutting-edge technology, robust infrastructure, and highly skilled personnel.

Data Security and Privacy

With increased data usage, businesses must implement robust data security and privacy protection measures to prevent breaches and ensure compliance with regulations. This addresses data security risks in supply chain data.

Resistance to Change

Shifting to data-driven practices often necessitates a profound cultural change within organizations, which can sometimes be met with resistance from employees accustomed to traditional methods.

Unlock The Power of Data & Aanalytics With Experts!

The Future of Data and Analytics in Supply Chains

The role of data and analytics in supply chain management is poised for continued, significant growth. Key trends to anticipate include:

- Increased Automation: AI and ML will increasingly enable more autonomous decision-making, substantially reducing the need for manual intervention.

- Real-Time Analytics: The widespread adoption of real-time analytics will further enhance supply chain visibility and responsiveness, allowing for immediate adjustments.

- Sustainability Analytics: Businesses will increasingly leverage sustainability analytics to precisely measure and effectively reduce their environmental impact, contributing to more sustainable practices.

- Collaborative Supply Chains: Data sharing and inter-organizational collaboration will become more widespread, enabling more effective end-to-end supply chain optimization across entire ecosystems.

Data analytics is revolutionizing supply chain management, offering essential tools to optimize operations, reduce costs, and boost customer satisfaction. Its role will only expand as technology advances, helping companies navigate complex global supply chains. Despite implementation challenges, the long-term benefits of data analytics in supply chain far outweigh obstacles. Embracing data and analytics in supply chain management is now crucial for handling disruptions, meeting demands, and securing sustained success in today’s dynamic marketplace. It’s no longer just an advantage—it’s essential.

Thanks For Reading: Power of Data and Analytics in Supply Chain Management

Powered By 360Presence

12 Comments

Comments are closed.