Understanding Supply Chain Operations

Any organisation that handles the production and distribution of goods operates through supply chain operations. Knowing how supply chain operations function remains vital for all business owners who run from small entities to large organisations because it ensures products move effectively from suppliers to customers.

This blog provides an explanation of supply chain operations together with their importance and essential components responsible for their functionality. You will finish this piece with full comprehension of supply chain operational methods alongside optimization techniques for achieving success.

The production and delivery of goods to customers depends on supply chain operations that include systems, activities and processes. The entire lifecycle of product delivery starts with material procurement, followed by manufacturing production, then continues through inventory storage until order fulfilment, and final delivery to customers.

Supply chain operations function like a choreographed dance performance. The successful delivery of a perfect product to customers requires precise planning and execution for each step of the process.

Why Are Supply Chain Operations Important?

Supply chain operations play a critical role in the success of any business. Here’s why they matter:

Customer Satisfaction: Efficient supply chain operations ensure timely delivery, which is key to keeping customers happy and encouraging repeat purchases.

Cost Efficiency: Streamlined operations reduce waste, lower costs, and improve profit margins.

Competitive Advantage: A well-managed supply chain can help you stand out by delivering faster and more reliably than competitors.

In short, supply chain operations directly impact your ability to grow your business and build a loyal customer base.

Key Components of Supply Chain Operations

1. Demand Planning

Demand planning represents the procedure of predicting product requirements to fulfil customer needs also known as demand forecasting. The process depends on historical sales data evaluation to determine patterns and handle seasonal effects. The use of accurate demand planning prevents both product overstocking and stock depletion.

2. Purchasing

The purchasing operations consist of supplier-based activities that involve both raw material and finished product acquisition. Negotiating with suppliers for product prices occurs together with developing purchase orders for materials before securing shipping logistics for products to arrive at your warehouse or manufacturer facilities.

3. Manufacturing

The manufacturing process converts unprocessed materials into final products through its operations. The manufacturing process can be handled through both internal production sites and collaborative agreements with outside manufacturers to deliver high-quality products within stated deadlines.

4. Inventory Management

The core principle of inventory management consists of organising and monitoring product storage. The process involves accepting deliveries of goods, followed by storage arrangement and stock monitoring to prevent running out of inventory while also preventing excessive stock accumulation. Multiple businesses deploy inventory management system or tools to automate their system operations.

5. Fulfillment & Warehousing

The fulfilment centre operations start when customers finalize their orders. Businesses must select the correct products before securely packing them for shipping operations. Businesses operating multiple warehouses need to properly position their inventory to guarantee quick delivery at competitive costs.

6. Shipping & Transportation

The delivery of packages through shipping operations reaches customers within their expected timeframes. The shipping process mainly relies on collaboration with shipping providers, such as Nscs, UPS, or FedEx. Real-time shipment tracking equipment enables you to track packages so you can handle slowdowns ahead of time.

7. Customer Service

The supply chain continues its operations after product delivery. The post-purchase service operations of customer service manage return procedures alongside refund requests and equipment maintenance. High-quality service interactions between customers and businesses will create long-term relationships from single-purchase shoppers.

Optimize Your Supply Chain Operations with Experts!

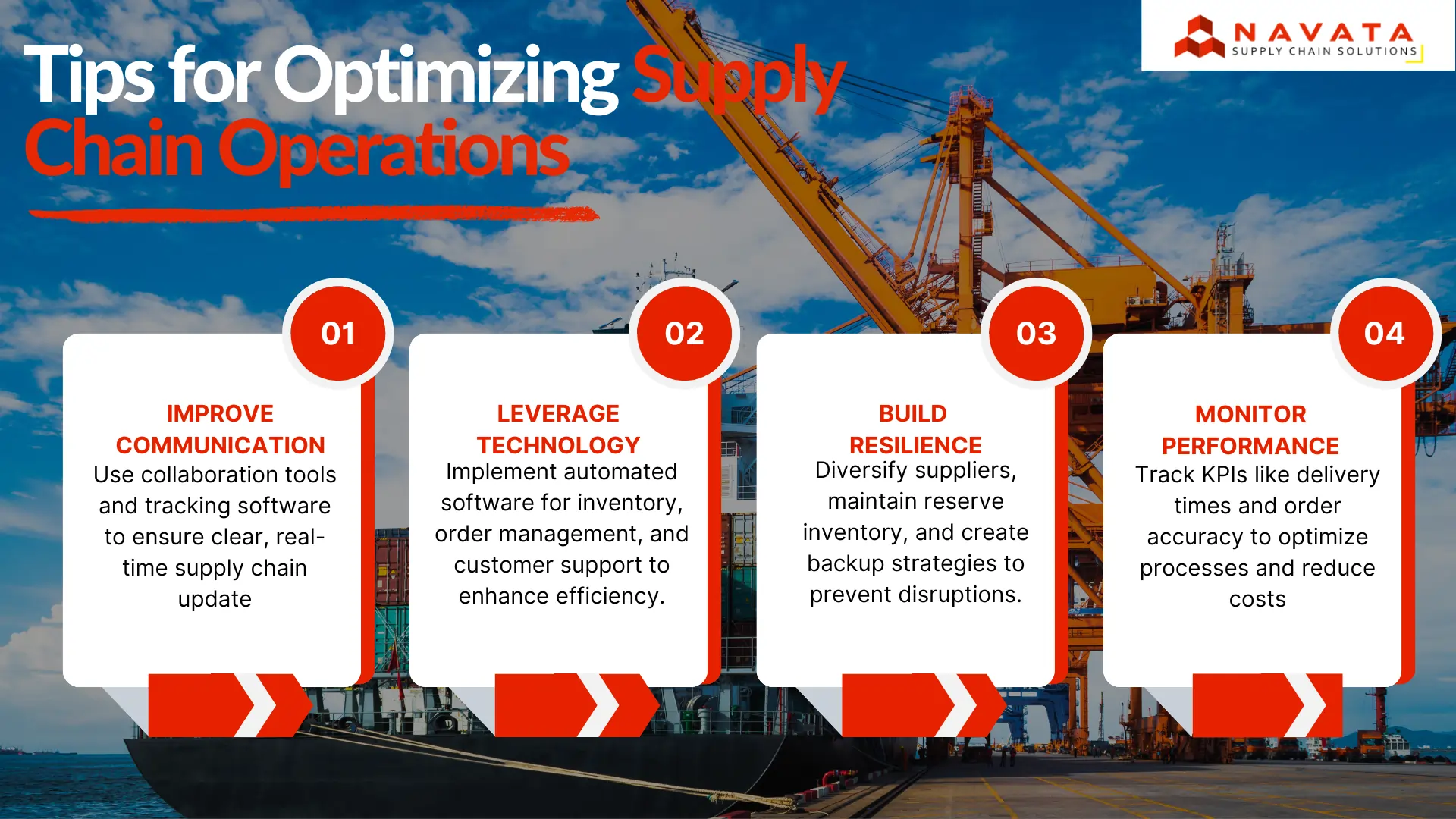

Tips for Optimizing Supply Chain Operations

To keep your supply chain running smoothly, follow these best practices:

1. Improve Communication

The success of supplier, manufacturer and delivery partner operations depends on clear communication channels. Provide collaboration tools alongside real-time tracking software, which maintains ongoing information sharing for all parties. By using regular updates and transparent processes, mistakes and misunderstandings, together with delivery delays, can be avoided, which allows your supply chain to function efficiently.

2. Leverage Technology

Your company should purchase state-of-the-art software applications which handle inventory tracking alongside order management and customer assistance operations. Automated software solutions automate regular work activities while removing human mistakes and delivering instantaneous data evaluation. The integration of platforms results in operational efficiency that enables smooth supply chain management.

3. Build Resilience

Your company needs to prepare for disruptions by choosing multiple suppliers, keeping reserve inventory, and creating backup strategies. Your business should identify possible risks, including delivery delays, market fluctuations, and natural disasters. Security within supply chains enables flexible adaptations to challenges that keep operational disruptions and customer satisfaction at low levels.

4. Monitor Performance

You should monitor performance by tracking KPIs that include delivery times, order accuracy, and inventory turnover. Analyzing operations on schedule allows businesses to locate performance blocks and find sites for improvement. Business organizations should apply data analytics to their supply chain operations for process optimization, cost reduction, and efficiency enhancement.

Conclusion

Supply chain operations are the unsung hero of business success. By understanding and optimizing each component, you can create a seamless experience for your customers while reducing costs and improving efficiency. Whether you’re just starting out or looking to refine your existing supply chain, focusing on these operations will set your business up for long-term growth

Thanks For Reading: What is Supply Chain Operations?

Powered By 360Presence