What is IoT?

The Internet of Things (IoT) is a system of connected devices that are capable of exchanging information over the Internet. Such devices as sensors, RFID tags, and other gadgets are intended for data gathering and transmitting making systems wiser and more effective. IoT relies on three key components: smart devices that gather information, connexion technologies such as Wi-Fi, Bluetooth, or cellular networks that allow sharing, and data processing systems which analyze the information gathered to help identify useful patterns.

All these components enable the automation of some tasks, enhance decision making and enhance the flow of different processes in different fields such as supply chain and logistics.

Challenges in Traditional Supply Chain and Logistics

Traditional supply networks suffer a number of issues that reduce efficiency and production. A key concern is a lack of real-time visibility, which makes it impossible to precisely track shipments and inventories. Inefficient inventory management frequently leads to overstocking or stockouts, resulting in lost revenue or higher storage expenses.

Delayed deliveries, whether due to poor route optimization or unplanned delays, can have an influence on customer satisfaction and corporate reputation. Furthermore, high operating expenses, caused by human procedures and obsolete technology, place a strain on profit margins, making it difficult to remain competitive. These difficulties underscore the need for creative solutions, such as IoT, to revolutionize the sector.

How IoT is Shaping Supply Chain and Logistics

Live Monitoring and Transparency

GPS-intensive devices can be made available through IoT in order to monitor shipment in real time. This helps to make the right changes of the location and state of goods without many complications. Customers and stakeholders get the advantage of increased transparency over operations which reduces uncertainties, timely deliveries, and better decision-making during transit.

Predictive Maintenance

IoT sensors are used to track the performance of vehicles and identify signs of downfall at an initial stage. Such predictive techniques significantly reduce the time required for repair and the total cost of repairs since issues are dealt with, at a very early stage. Companies perform better due to reduced downtime of business and operations; the supply chain is not disrupted through timely fixes of breaks down that might have a damning effect on productivity.

Enhanced Inventory Management

IoT picks the continuous tracking of inventories in smart stocks resulting in the reinvention of inventory management. It helps to minimize on situations where stocks are either over-bought or under-bought hence achieving the right stock levels. Accuracy in stock must be well observed because it helps businesses cut down their expenditure and wastage of stocks as they as are able to meet their customer’s needs and enjoy better productivity.

Improved Fleet Management

IoT devices optimize fleet operations by analyzing data to plan efficient delivery routes. This reduces fuel consumption, improves delivery times, and enhances driver performance. Businesses benefit from reduced operational costs, better resource utilization, and increased reliability in their logistics networks.

Automation in Warehousing

IoT-powered robotics and Automated Guided Vehicles (AGVs) perform repetitive tasks, enhancing productivity and precision. Automation reduces human errors, speeds up operations, and optimizes space utilization in warehouses. This technological shift allows businesses to handle higher volumes with greater accuracy and efficiency

Data-Driven Decision Making

IoT generates actionable insights by analyzing data from connected devices. Businesses use these insights to improve strategies, reduce inefficiencies, and address challenges proactively. Faster and more accurate decision-making enhances the overall performance of the supply chain, boosting customer satisfaction and profitability.

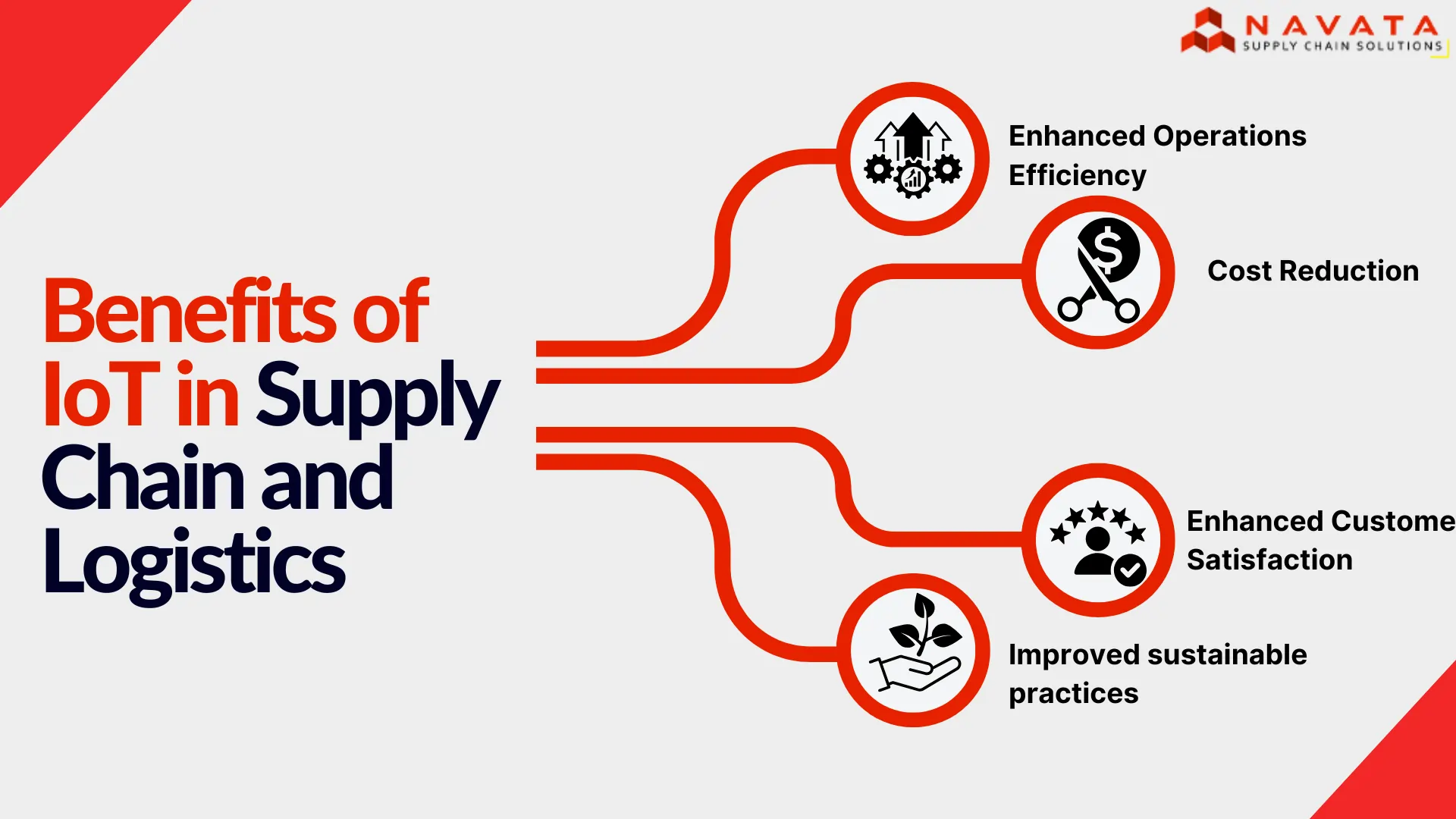

Benefits of IoT in Supply Chain and Logistics

Enhanced Operations Efficiency

IoT improves the supply chain visibility through the use of technology to automate operations, plan for the best routes, and track physical assets. This makes it possible to process these issues within a shorter time and with a lot of precision so that production has not to be halted to work on them. Companies gain the ability to successfully coordinate a vast number of logistics operations while keeping the resource flow in cheque.

Cost Reduction

Through IoT devices, fuel consumption, unnecessary repairs and wastage in the management of inventory can be solved. This optimization means a direct decrease in operating expenses. Advanced tracking technologies improve supply chain efficiency enabling the allocation of resources in a more sophisticated manner fulfilling the goal of achieving the highest possible returns for all investments in supply chain management.

Enhanced Customer Satisfaction

IoT makes it possible to track delivery and get(shipments) and predictive analytics to enhance the timely delivery of products. Customers gain improved transparency, timely updates, and greater levels of trust to be provided consistently to improve service quality. Faster deliveries also enhance the competitive image of several brands in the market.

Improved sustainable practices

IoT plays a significant role in promoting environmentally friendly supply chains by utilizing fuel, lowering emission rates and almost eliminating waste. Energy efficiency is achieved by the use of smart sensors to control the use of energy and imply sustainable usage. Companies using IoT not only seek cost optimization but also get closer to the sustainable development objectives set on a global level.

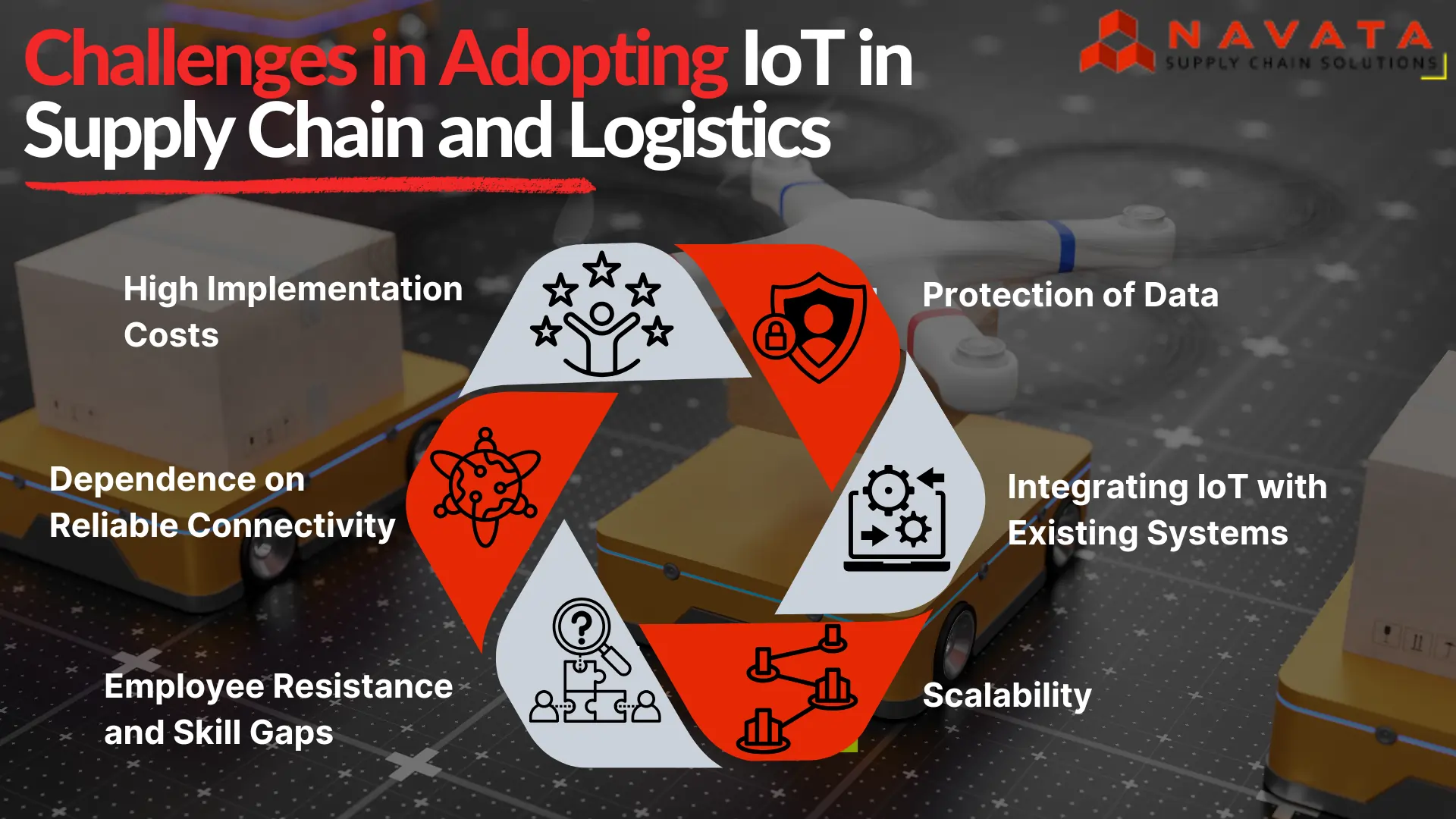

Challenges in Adopting IoT in Supply Chain and Logistics

High Implementation Costs

The utilization of IoT solutions in supply chain and logistics management always involves substantial fixed costs in terms of machinery such as sensors, RFID, GPS, etc., as well as connexions and cloud storage. In addition to the required and non-required expenditures, there are ongoing costs related to the devices themselves, the software, and training employees to use the devices. Such costs can be very expensive to SMEs who have to work with limited budgets to fund their undertakings. Furthermore, proving the value of IoT implementation to the business, is not always easy at first, so a company is not helped when it comes to expenses.

Protection of Data

IoT systems operate on the basis of continuous data transfer and thus can fall prey to cyber criminals. Criminals can easily breach IoT systems and access valuable operational information or take control of the flow of work or of installations. Supply chain risks and logistics risks become more devastating because leakage of information will impact areas such as inventory, delivery schedules, and customer relations. Businesses and organizations must use current and enhanced security standards like end-to-end encryption, firmware upgrades, and security access features like credentials. However, these steps may lead to the enhanced complication and expense of incorporating IoT into an organization.

Integrating IoT with Existing Systems

The majority of businesses are dependent on older inventory management systems which do not inherently integrate with IoT applications. Adapting new IoT devices to an existing system can cause technical issues like: data structure mismatch, system compatibility issues, and process divergence. This integration process also may take a long time and can include the use of specialist knowledge, testing, and development of further programs. Moreover, the transition period is an exertion to disrupt ongoing business operations and may have an impact on the organization’s effectiveness and customer satisfaction. Decision-makers also have to include other factors addressing the challenges of integrating multiple IoT sources into central analytical and decision-making hubs in business landscapes.

Scalability

That is why, when companies drift into putting together massive IoT networks, they look at scale as well. Introducing new devices in the system or just confirming that they are incorporated properly into the existing system, is quite challenging. Individual IoT devices may also have different protocols of operation agreed with the manufacturing companies, and this may cause complex interoperability. This challenge can reduce the maneuverability of businesses to obtain the best-fit devices or systems for their requirements. Realizing scalability and interoperability frequently means embracing standard solutions and purchasing middleware systems which can add to already heavily pressured costs and schedules.

Employee Resistance and Skill Gaps

The adoption of IoT on the other hand may face some challenges from employees who are inapplicable to the technology. Employment insecurity arises from concerns of automation and loss of jobs as well as from pressure of developing new competencies. In the same way, it may be difficult for businesses to acquire human capital with knowledge in fields such as IoT, data analytics, and cybersecurity. The development of the IoT is likely to be a time-consuming and expensive undertaking since it requires the training of existing employees and the recruitment of new personnel for the systems’ creation.

Dependence on Reliable Connectivity

One major concern recognized in IoT systems is that the networks rely more on continuous, efficient, and reliable internet connection for collecting or forwarding data in real-time platforms. Specifically, when there are fewer networks in areas like remote warehouses or transport routes, IoT work can be problematic. These can result to differ end outcomes such as delay, loss of data, and erroneous decisions that affect the reliability of IoT solutions.

Future of IoT in Supply Chain and Logistics

The future of IoT in supply chain and logistics holds immense potential for transformation. Advancements in technologies like 5G and edge computing are set to enhance IoT capabilities, enabling faster data transmission and real-time decision-making by processing data closer to its source. Autonomous vehicles and drones, powered by IoT, will revolutionize transportation and delivery by improving speed, reducing fuel consumption, and expanding reach to remote areas. Artificial Intelligence (AI) will further enhance IoT functionality, using predictive analytics to optimize inventory, forecast demand, and streamline operations.

Sustainability will also take center stage, with IoT playing a pivotal role in monitoring resource usage, reducing waste, and achieving greener supply chains. Integration with blockchain will add a layer of transparency and trust, providing end-to-end visibility and combating issues like counterfeiting and unethical practices. With these advancements, IoT is poised to drive unprecedented efficiency, innovation, and sustainability in supply chain and logistics, reshaping the industry’s future.

Thanks For Reading: What is IoT and how it is Shaping supply chain & Logistics

Powered By 360Presence