What Are Automated Guided Vehicles (AGVs)?

Automated Guided Vehicles (AGVs) are self-operating, computer-controlled vehicles used to move materials and goods within facilities such as warehouses, distribution centers, factories, and even hospitals. If you’re wondering what are Automated Guided Vehicles (AGVs)?, they are essentially driverless transport systems that operate without a human driver and follow predefined paths using technologies like:

- Magnetic tape

- Laser guidance

- Sensors and cameras

- GPS (for outdoor navigation)

These vehicles are designed to perform repetitive tasks like transporting goods from one part of the warehouse to another, freeing up human workers for more complex or decision-based tasks.

You May Also Like to Read: Warehousing Technologies: 5 Latest Trends

What Are the Key Applications of AGVs in Warehousing and Logistics?

AGVs offer a wide range of applications that streamline daily operations:

- Material Transport

AGVs move raw materials, finished products, or components from one station to another. This is especially useful in production lines, assembly areas, and packaging stations.

- Order Fulfillment

In e-commerce and retail warehousing, AGVs assist in picking and packing operations. Some models even work in tandem with warehouse staff, enhancing collaborative picking efficiency.

- Inbound and Outbound Logistics

AGVs help with the unloading of trucks, sorting of goods, and moving items to outbound docks—all while reducing human intervention and the risk of errors.

- Cold and Hazardous Environments

In industries like pharmaceuticals and chemicals, AGVs work in cold storage or hazardous zones, protecting employees from extreme conditions.

How Do Automated Guided Vehicles Work?

AGVs combine multiple technologies to ensure seamless navigation and task execution:

- Navigation Systems: AGVs follow routes defined by magnetic tape, QR codes, lasers, or SLAM (Simultaneous Localization and Mapping) technology.

- Obstacle Detection: Equipped with sensors, LIDAR, and cameras, AGVs detect obstacles and stop or reroute to avoid collisions.

- Fleet Management Software: A central system assigns tasks to AGVs, tracks real-time status, and optimizes routes for maximum efficiency.

- Battery Management: Smart AGVs automatically return to charging stations when idle or low on power, allowing 24/7 operation.

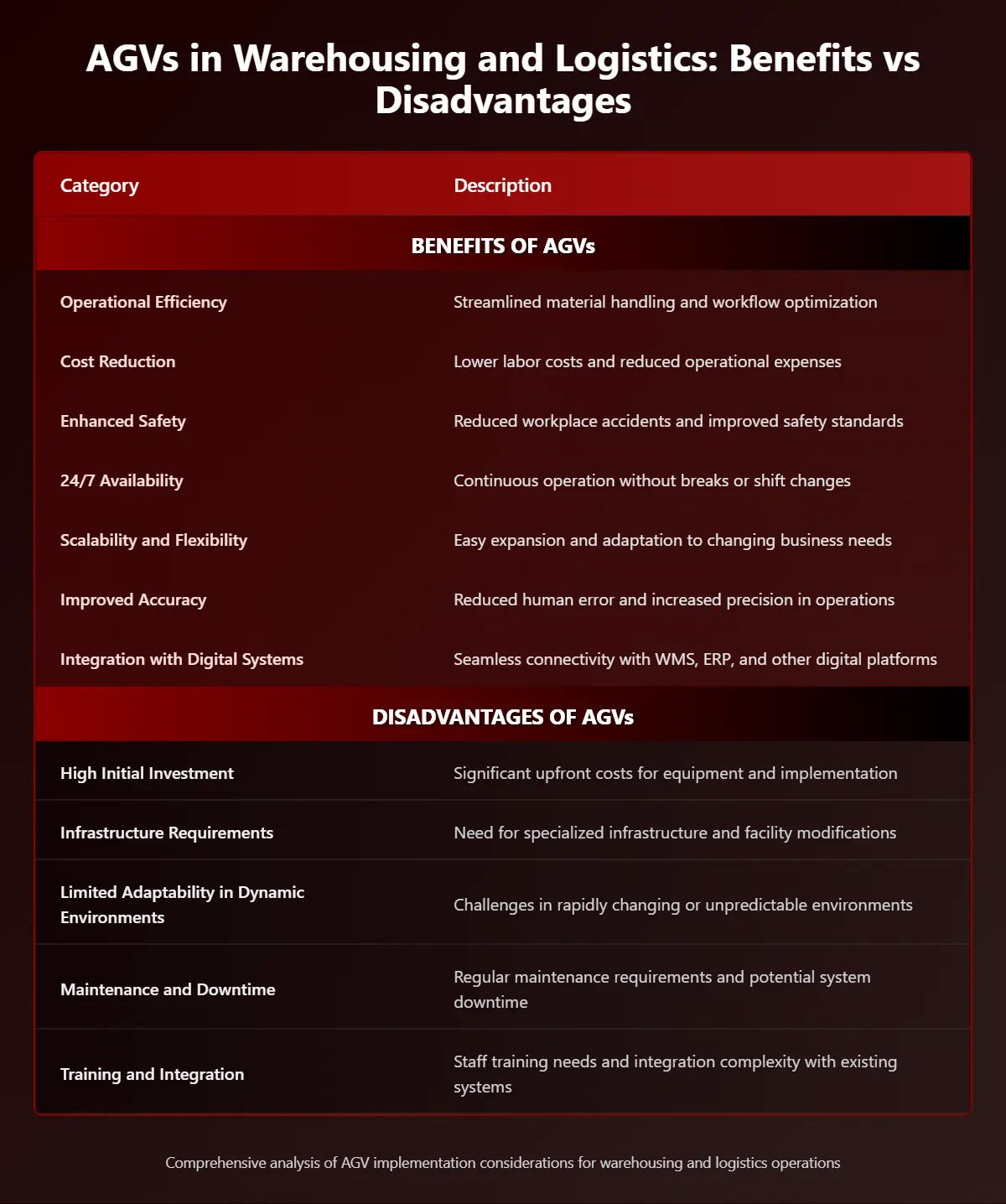

What Are the Benefits of AGVs in Warehousing and Logistics?

Automated Guided Vehicles (AGVs) offer multiple advantages that are transforming both warehousing and logistics operations. These intelligent machines help organizations meet increasing demands for speed, accuracy, and safety in the supply chain.

- Operational Efficiency: AGVs perform repetitive tasks like material handling, pallet movement, and order transport with high consistency. This boosts daily throughput without slowing down due to fatigue or human error.

- Cost Reduction: By automating routine operations, businesses can lower labor costs and reduce the need for additional workforce during peak times or labor shortages.

- Enhanced Safety: AGVs are equipped with sensors and obstacle detection systems that minimize workplace accidents. In hazardous zones or cold storage, they help keep human workers safe by handling risky operations.

- 24/7 Availability: Unlike human labor, AGVs can operate continuously. With smart battery management, they recharge during idle periods, allowing round-the-clock performance without interruption.

- Scalability and Flexibility: AGV systems can grow with your business. Whether expanding a facility or adapting to seasonal demand, companies can easily add more AGVs or reconfigure paths to meet operational needs.

- Improved Accuracy: AGVs follow precise instructions and navigation paths, reducing errors in picking, packing, and material delivery. This results in better inventory management and customer satisfaction.

- Integration with Digital Systems: Many AGVs integrate with warehouse management systems (WMS) and ERP platforms, allowing real-time tracking, automated reporting, and data-driven decision-making.

What Are the Disadvantages of AGVs in Warehousing and Logistics?

While AGVs offer many advantages, they also have some limitations:

- High Initial Investment: Purchasing AGVs and implementing supporting systems (like sensors, software, and layout adjustments) can be expensive. While they offer long-term savings, the upfront cost may be too steep for small or mid-sized businesses.

- Infrastructure Requirements: Some AGVs require modifications such as magnetic strips, floor guides, or dedicated paths. These changes can limit flexibility and demand additional setup time.

- Limited Adaptability in Dynamic Environments: Traditional AGVs work best in controlled, predictable spaces. If the layout frequently changes or if the space is cluttered, AGVs may struggle to navigate effectively.

- Maintenance and Downtime: AGVs require regular maintenance. A malfunction or software error can interrupt workflows unless there’s a backup system in place.

- Training and Integration: Implementing AGVs involves training staff and integrating them with existing systems like warehouse management software (WMS), which can take time and planning.

You May Also Like To Read: Artificial Intelligence and Machine Learning in Supply Chain

Conclusion

Automated Guided Vehicles are rapidly becoming a core component of modern warehousing and logistics strategies. By automating routine tasks, they not only enhance operational efficiency but also create safer and more reliable work environments. As technology evolves, AGVs are becoming smarter, more adaptable, and better integrated with systems like WMS and AI-driven analytics.

Whether it’s reducing labor dependency, speeding up order fulfillment, or optimizing inventory movement, AGVs offer long-term value for warehouses aiming to stay competitive. For companies looking to scale, improve safety, or modernize their logistics infrastructure—AGVs are no longer an option. They are a necessity.

Thanks For Reading: What are Automated Guided Vehicles(AGVs)?: Transforming Warehousing and Logistics

Powered By 360Presence