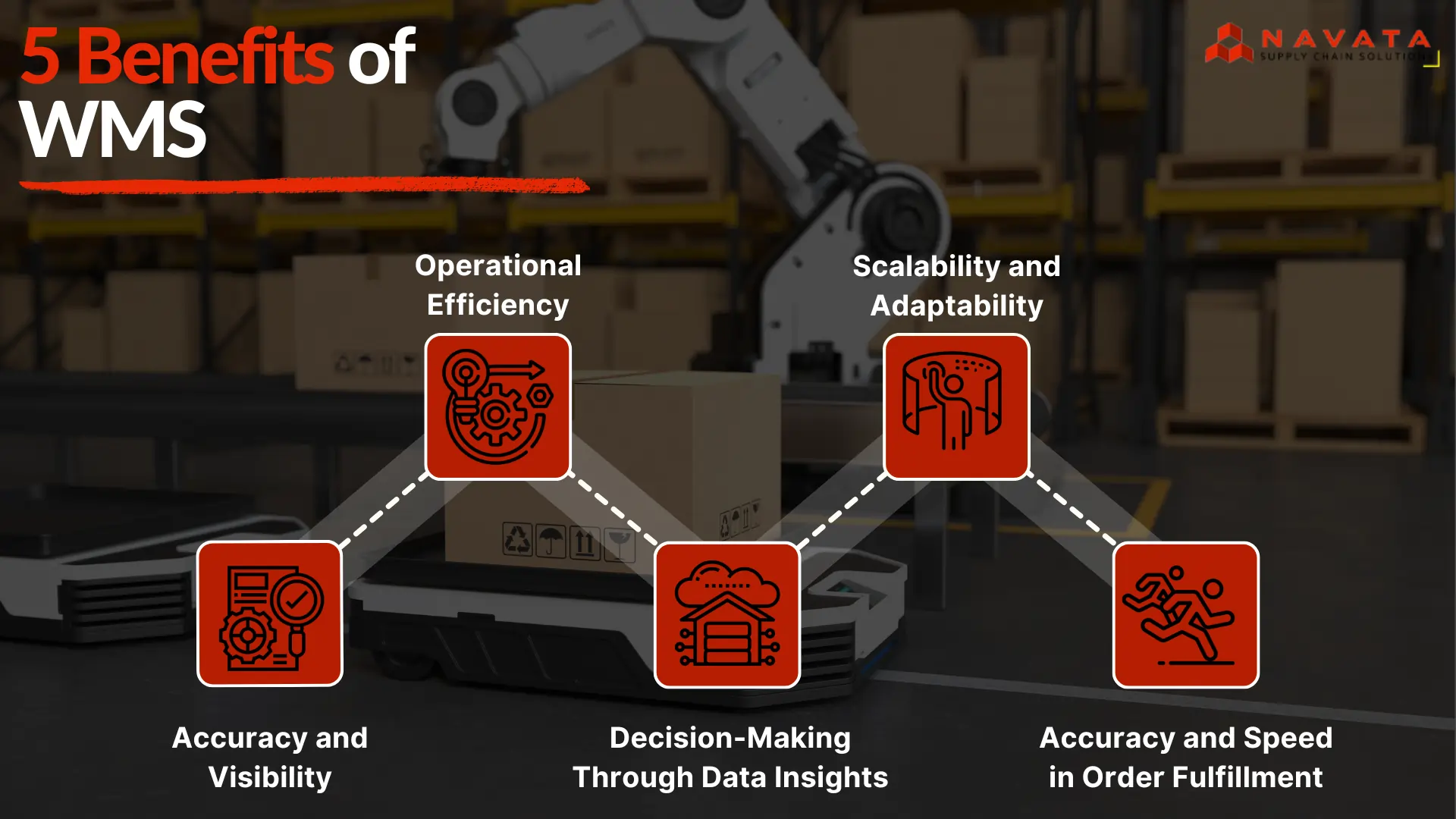

Benefits of Warehouse Management Systems

If you want to conquer the realm of modern logistics and supply chain management, then efficiency is the name of the game. As more and more businesses join the race to compete against the growing demands of consumers while simultaneously managing intricate inventories, technology becomes crucial for ensuring success. Among the vast arsenal of advanced technological tools available to streamline operations, Warehouse Management Systems (WMS) stand out as indispensable assets. These robust platforms offer a great number of benefits that can revolutionize the way warehouses function. Let’s delve into the five key benefits of Warehouse Management Systems.

Accuracy and Visibility

One of the biggest challenges you will face in warehouse management is maintaining accurate inventory records. Manual tracking methods may have worked in the past but in today’s accelerated market, they are prone to errors. This leads to discrepancies between the recorded stock levels and the actual inventory. This gap can result in stockouts, overstocking, misplaced items, and ultimately- dissatisfied customers.

A Warehouse Management System can help resolve each of these issues by providing real-time updates into inventory levels and locations. By utilising tools such as barcode scanning, RFID technology, and automated data capture, WMS ensures accurate tracking of each and every item within the warehouse. This heightened visibility enables precise inventory management. This helps businesses optimize their stock levels, reduce carrying costs, and minimize the risk of stockouts or excess inventory. All this results in minimum wastage and maximum profit margins.

Operational Efficiency

Efficiency lies at the heart of every successful business operation. When it comes to warehouse operations, using Warehouse Management Systems can streamline workflows and processes, eliminating all bottlenecks that impede productivity. This boosts accuracy and efficiency in operations. Furthermore, by automating tasks such as order processing, picking, packing, and shipping, WMS yields greater output while also reducing labor costs and shortening operational cycles at the same time.

Additionally, since WMS utilizes advanced algorithms and optimization techniques, it results in refined warehouse layout and storage strategies. It assigns optimal positions for storing specific products on the basis of factors like demand frequency and storage capacity. Thus, it maximizes space utilization and minimizes travel time for pickers. This results in faster order fulfillment, reduced labor fatigue, and overall operational excellence.

Accuracy and Speed in Order Fulfillment

In today’s fast-paced business environment, consumers are adept to fast order fulfilment without any scope of error. Thus, any delay or mistakes can completely tarnish a company’s image, driving customers to competitors. This is where Warehouse Management Systems become crucial. They play a pivotal role in meeting consumer expectations by facilitating seamless order fulfillment.

WMS leverages automated order prioritization, route optimization, and real-time inventory updates. This ensures that orders get picked, packed, and shipped in a timely manner. Barcode and RFID technology help in ensuring accuracy by virtually eliminating picking errors and misplacements. As a result, businesses can deliver orders promptly, accurately, and consistently, fostering customer satisfaction and loyalty.

Also Read: Emerging Warehouse Automation

Decision-Making Through Data Insights

Data is the new gold for businesses and the lifeblood for effective decision-making in the modern business landscape. The beauty of Warehouse Management Systems is that they can generate a wealth of data regarding warehouse operations, inventory movements, order patterns, and much more. Businesses can leverage this data to make strategic decisions on how to improve operational efficiency. This process can be accelerated further by employing advanced analytics and reporting capabilities of the WMS.

Not just decision making but WMS also help refine business functions. For instance, store managers can utilize WMS to identify trends, anticipate demand fluctuations, and optimize inventory replenishment strategies. By analyzing past data and performance metrics, businesses can fine-tune their operations, improve forecasting accuracy, and mitigate risks. Ultimately, data-driven decision-making facilitated by WMS leads to better resource allocation, cost savings, and gives businesses a competitive advantage over others.

Scalability and Adaptability for Business Growth

In today’s dynamic and ever-evolving marketplace, scalability and adaptability are crucial for ensuring sustained success. Warehouse Management Systems are designed to scale alongside businesses, accommodating growth, expansion, and changing operational requirements.

The best part is that WMS are extremely adaptable. Irrespective of whether a business operates a single warehouse or a network of distribution centers, WMS can be tailored to meet its specific needs and scale accordingly. The modular architecture and versatile design of a WMS makes room for seamless integration with other enterprise systems such as Enterprise Resource Planning (ERP) and Transportation Management Systems (TMS). This ensures interoperability and data consistency across the organization.

Furthermore, WMS providers continuously innovate and update their platforms to incorporate the latest technologies and best practices. This ensures that businesses remain agile and competitive in the face of evolving industry trends and customer demands.

Conclusion

There are many benefits presented by Warehouse Management Systems. They are multifaceted tools that can drive operational efficiency and boost profit margins of a business. WMS play many functions, ranging from ensuring inventory accuracy to facilitating data-driven decision-making and promoting business growth. WMS serve as indispensable tools for modern warehouse management. By leveraging this powerful technology, businesses can unlock new levels of growth, satisfying customer needs and making timely decisions.

Thanks For Reading: The 5 Key Benefits of Warehouse Management Systems

Powered By 360Presence

FAQ

What is Warehouse Management Systems (WMS)?

Warehouse Management Systems is software platforms designed to optimize warehouse operations. It use technology like barcode scanning and RFID to track inventory, streamline processes such as order fulfillment, and enhance overall efficiency.

What is the use of data insights in warehouse management?

WMS data insights enable businesses to make more informed decisions by studying operational indicators, inventory trends, and order patterns. This increases strategic planning, forecasting accuracy, and resource allocation to get better company results.

Which technologies are used in Warehouse Management Systems?

WMS use technologies such as barcode scanning, RFID, and automation tools for inventory tracking and management. These technologies enhance accuracy, efficiency, and operational transparency within warehouses.

Benefits of Warehouse Management Systems in supply chain management?

WMS optimize inventory control, streamline logistics processes, and enhance visibility across the supply chain. This improves inventory accuracy, reduces costs, and enables businesses to meet customer demands effectively.

How do Warehouse Management Systems optimize warehouses?

WMS optimize warehouse by analyzing inventory data and demand patterns. They assign optimal storage locations for products, reducing travel time for pickers and enhancing space utilization for better efficiency.