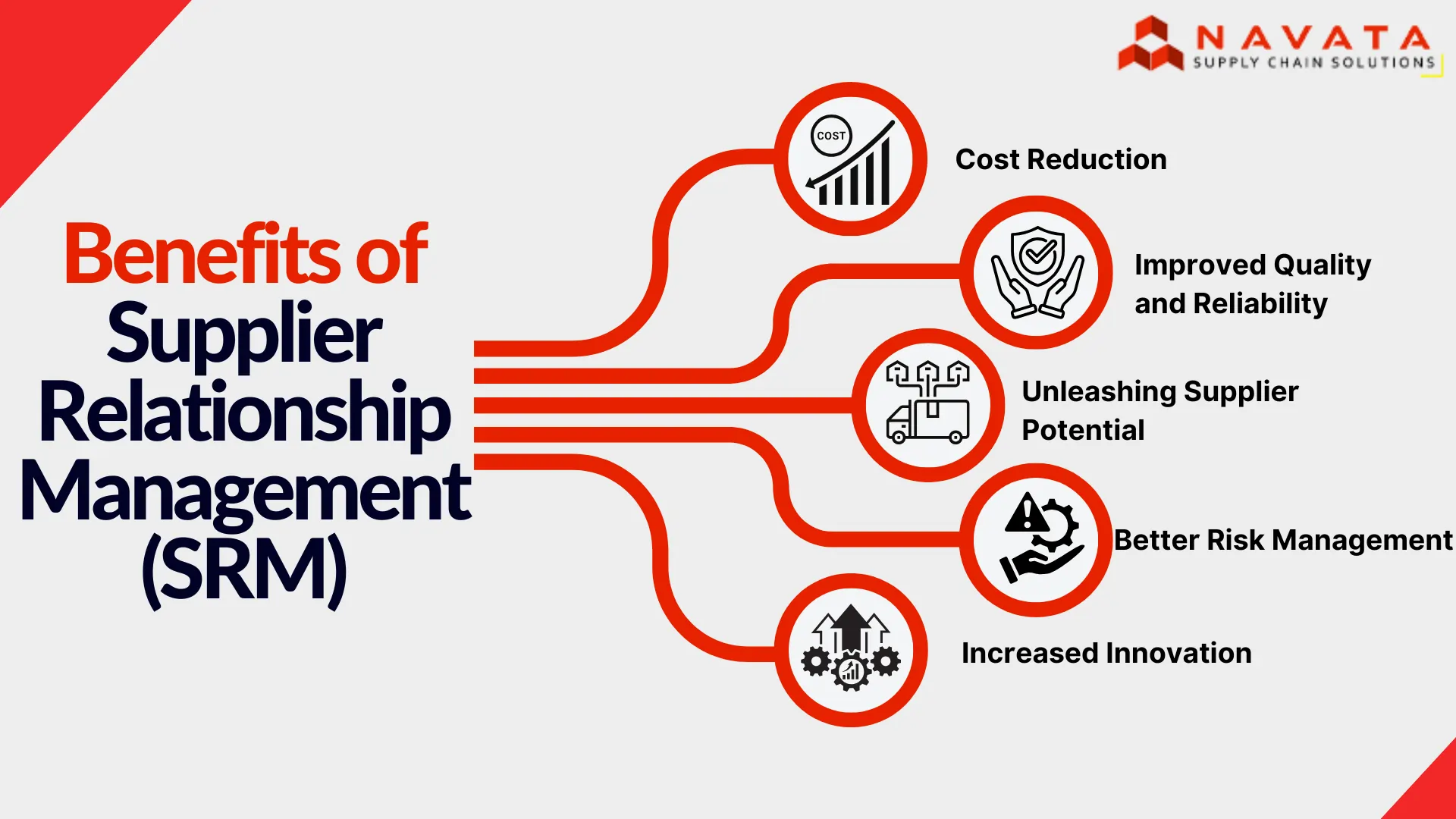

Benefits of Supplier Relationship Management (SRM)

The modern business environment requires many different entities to guide products or services through their complete lifecycle until they reach customer ownership. Among these crucial players are our suppliers – the businesses that provide us with the materials, components, and services we need to operate and thrive.

The supplier relationship maintained for too many years was mainly transactional because it involved exchanging goods in exchange for payment. Modern companies understand that their current supplier relations system fails to extract maximum value from their supplier. They are embracing a more strategic and collaborative approach known as Supplier Relationship Management (SRM).

SRM represents a method for forming powerful alliances between essential suppliers which produces better results compared to basic vendor management practices. The development of trust combined with open communication and with shared goals enables organizations to access significant advantages that directly affect their financial success.

SRM functions by developing robust supplier connections to produce enhanced business results. It’s about fostering trust, open communication, and shared goals to unlock a wealth of advantages that can significantly impact your bottom line and overall success.

Stronger supplier relationships lead to better business outcomes. But what exactly are these “better outcomes”? Let’s delve into the tangible benefits of Supplier Relationship Management (SRM) strategy can bring to your organization.

1. Power of Savings: Cost Reduction

Every business depends on cost control as its fundamental requirement. Through SRM, organizations can access multiple methods to reduce costs substantially.

Negotiated Pricing

Your deep knowledge about supplier costs, combined with solid relationships, allows you to move past basic price negotiation. You can conduct better price negotiations to secure bulk discounts and establish long-term agreements with beneficial terms as well as launch joint cost-reduction projects. Suppliers who experience value and understanding from your company will work more cooperatively on pricing matters.

Reduced Total Cost of Ownership (TCO)

SRM extends beyond the initial purchase price because it examines comprehensive organizational costs. The method analyzes the complete set of expenses that extend across the product or service lifecycle. You can substantially decrease costs concerning rework, returns, maintenance, and disposal expenses through supplier process optimization that identifies inefficiencies and ensures initial quality standards. A trustworthy supplier who grasps your requirements will protect you from future expenses in your supply chain management.

Process Optimization

Your suppliers will help you optimize processes from start to finish by working together. You should work with suppliers to enhance order placement operations while optimizing logistics, developing more effective communication platforms, and integrating system platforms for smooth data sharing. The implemented efficiencies produce lower administrative expenses and shorter processing durations, which result in operation cost savings.

Optimize Your Supplier Realtionship With Experts!

2. Improved Quality and Reliability

Poor quality alongside unreliable delivery services will break down your operations while simultaneously harming your brand reputation and losing customer trust. SRM establishes fundamental operational elements that deliver both quality consistency and supply reliability.

Quality Assurance

The development of authentic partnerships through mutual trust and respect makes suppliers dedicate more effort toward your organizational success. Such suppliers demonstrate enhanced dedication to product quality excellence by delivering exceptional service while making your requirements central to their activities. Through open communication, organizations can detect quality issues at an early stage before they develop into major problems.

Supplier Performance Monitoring

SRM requires organizations to define measurable performance indicators, which they evaluate against their supplier performance through consistent monitoring. Through this method you can detect superior suppliers for recognition while you also work to fix weak points in their performance. Consistent feedback and collaborative problem-solving drive continuous improvement in quality and reliability.

Minimizing Disruptions

Supply chain disruptions that occur unexpectedly generate serious negative effects. Your company benefits from supplier relationships that act as protective measures during sudden disruptions. During times of crisis, your business will receive proactive communication and alternative solutions when working with collaborative suppliers who help you reduce operational disruptions.

3. Unleashing Supplier Potential

Each supplier brings a distinctive set of expertise together with capabilities. Through SRM you gain access to supplier expertise, which enables better performance of your own organization.

Improved Communication and Collaboration

SRM establishes open communication channels that exist throughout every organizational level. A collaborative atmosphere develops when information moves without restrictions thus improving mutual understanding about requirements and difficulties. Higher levels of collaboration through SRM enable better problem resolution and goal synchronisation, which produces enhanced supplier performance.

Clear Expectations and Feedback

SRM demands organizations to specify exactly what they expect from suppliers in terms of quality standards, delivery schedules, service levels, and performance metrics. Regular feedback that includes constructive positive and negative elements helps suppliers understand their success areas and their improvement zones. Through continuous feedback between organizations and suppliers, the performance enhancement cycle remains active.

Supplier Capability Utilization

Your suppliers maintain expertise together with technological capabilities and resource assets that your organisation can use. Through SRM, organizations can discover and access their supplier capabilities. Your organization can enhance performance and gain market leadership by asking suppliers to join product development activities or by requesting their expertise for process enhancement.

4. Better Risk Management

The contemporary supply chain operates through intricate networks that face numerous potential dangers, including economic instabilities and international developments. SRM offers both tools and insights that help organizations better handle their supply chain risk management.

Supply Chain Visibility

Through SRM, you gain better visibility of your supply chain operations. Better visibility into potential risks emerges through your understanding of supplier operations along with dependencies and vulnerabilities. The identification process enables you to detect possible disruptions so you can evaluate them before they create business problems.

Supplier Risk Assessment

SRM relies heavily on the organised evaluation of supplier-related threats. The assessment process includes an evaluation of financial stability combined with operational capabilities and regulatory compliance together with geopolitical risk assessment. The identification of potential supplier risks enables you to create protective measures, such as building a diverse supply network with backup plans in place.

Reducing Dependence and Vulnerability

While building strong relationships with key suppliers is crucial, SRM also recognizes the importance of diversifying your supply base. By cultivating relationships with multiple reliable suppliers, you reduce your dependence on any single source and mitigate the risks associated with supplier failure or disruption.

5. Increased Innovation

Any successful business depends completely on innovation as its fundamental driving force. SRM serves as a strong innovation driver that allows organizations to establish deeper relationships with suppliers.

Spark of New Ideas

The strategic partnership approach with suppliers allows you to unlock collaborative innovation possibilities. Your business can benefit from supplier participation in research and development sessions because they bring novel insights to solve problems together.

Access to New Technologies

The suppliers within various industries remain at the leading edge of technological progress in their domains. The development of strong partnerships gives you first access to emerging technologies, which results in improved business performance. The collaboration between companies leads to co-developed innovative products and processes.

Faster Time to Market

Your suppliers’ expertise and capabilities enable you to shorten product development times, which results in quicker market releases for your new products. Through collaborative design and efficient production processes connected to strong supplier relationships, organizations can shorten their innovation development timelines.

Conclusion

Supplier Relationship Management is far more than just managing contracts and processing invoices. It’s a strategic approach that recognizes the immense value that strong, collaborative relationships with your suppliers can bring. By focusing on cost reduction, improved quality and reliability, enhanced supplier performance, better risk management, and increased innovation, SRM empowers your organization to build a more resilient, efficient, and competitive supply chain.

Embracing SRM is an investment in the future of your business. It’s about building bridges of trust and collaboration, transforming transactional relationships into strategic partnerships that drive mutual success and unlock a world of opportunities.

Thanks For Reading: Benefits of Supplier Relationship Management (SRM)

Powered By 360Presence