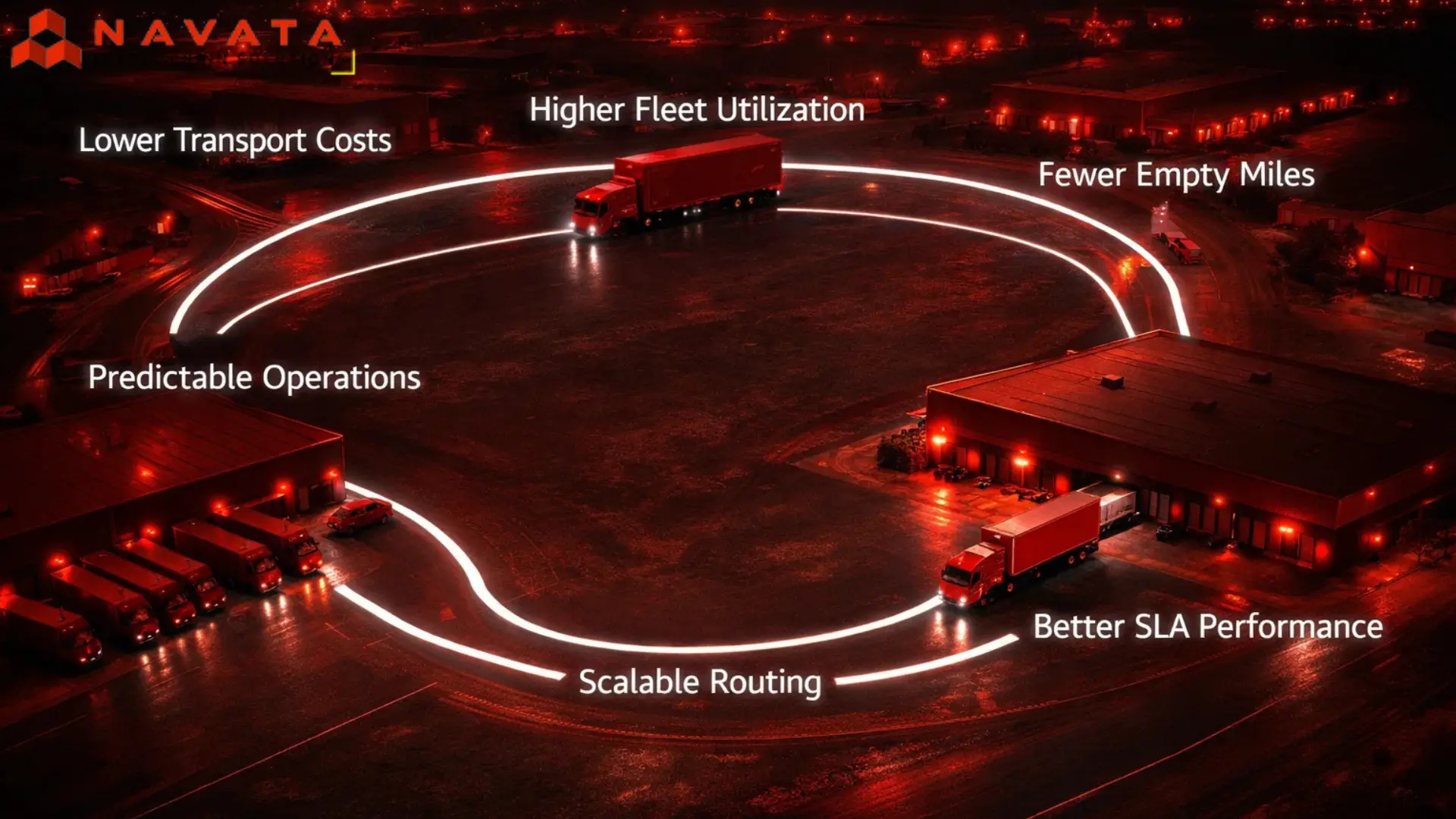

Benefits of Milk Run Model

In logistics, inefficiency rarely announces itself loudly. It hides in half-filled trucks, repeated dispatches, idle time at docks, and routes that look fine on paper but waste money in reality.

The Milk Run model was designed to fix exactly these problems. By replacing fragmented, point-to-point movements with planned multi-stop routes, it brings structure to daily transportation. When implemented well, its benefits extend beyond cost savings into fleet productivity, operational predictability, and service reliability.

Read About: What Is an OMS (Order Management System)?

1. Lower Transportation Costs Through Smarter Consolidation

One of the clearest advantages of the Milk Run model is cost efficiency. Instead of sending separate vehicles for individual pickups or deliveries, a single truck serves multiple locations along a planned route.

This approach:

reduces fuel consumption per shipment

lowers driver cost per movement

cuts down unnecessary vehicle dispatches

Over time, transportation spend becomes easier to forecast and less vulnerable to last-minute routing decisions.

2. Better Fleet Utilization and Asset Productivity

Fleet efficiency improves when trucks spend more time carrying freight and less time waiting or running empty. Milk Run routes are designed to balance load volumes across stops, ensuring vehicles operate closer to their optimal capacity.

Fixed schedules also improve driver planning and reduce idle vehicle time. For fleet managers, this translates into clearer visibility on asset usage and better control over maintenance and capacity planning.

3. Fewer Empty Miles and Reduced Idle Time

Empty miles are one of the most expensive inefficiencies in road logistics. The Milk Run model tackles this directly by creating circular or loop-based routes where vehicles remain productive for most of the journey.

Because pickup and delivery windows are pre-coordinated, trucks spend less time waiting at docks. Turnaround times improve, and daily operations feel more controlled instead of rushed.

4. Greater Predictability in Daily Operations

Predictability is often more valuable than flexibility at scale. Milk Run routes operate on fixed, repeatable schedules, allowing teams across the network to plan with confidence.

Warehouses know when trucks will arrive. Suppliers prepare loads in advance. Dispatch teams stop firefighting. This rhythm reduces congestion, miscommunication, and last-minute changes that disrupt operations.

5. Stronger Support for SLA and OTIF Performance

Consistent execution directly supports service-level commitments. When routes follow a defined pattern, delays become easier to anticipate and manage before they impact customers.

Milk Run models help protect OTIF performance by reducing:

late pickups caused by ad-hoc dispatching

delivery variability due to capacity shortages

missed cut-off times

This reliability is especially valuable in B2B and retail networks where delivery performance directly affects customer trust.

6. Reduced Dependence on Emergency Freight

Unplanned transport decisions often lead to premium freight, express vehicles, or rushed routing changes — all of which increase cost and operational stress.

By planning recurring movements into structured Milk Run routes, organizations reduce the need for emergency interventions. Transportation shifts from reactive problem-solving to planned execution.

7. Improved Coordination Across Multiple Locations

Milk Runs introduce discipline across the network. Fixed pickup and delivery windows force alignment between suppliers, warehouses, and transport teams.

This shared structure reduces ambiguity around responsibilities and timings, making coordination smoother and exceptions easier to resolve.

8. Better Alignment With Inventory and Warehouse Planning

When transportation follows predictable cycles, inventory planning becomes more stable. Warehouses can align putaway, picking, and dispatch activities with known inbound and outbound movements.

This improves space utilization, labor planning, and inventory accuracy — especially in environments handling frequent replenishment or multiple SKUs.

9. Scalable Growth Without Linear Cost Increases

As volumes increase, the Milk Run model allows growth without proportionally increasing fleet size or dispatch complexity. Additional volume is absorbed by optimizing routes or adjusting frequency, rather than adding new point-to-point movements.

This makes the model well-suited for growing logistics networks seeking efficiency without losing control.

You May Also Like to Read: What is RFID Technology & How It Is Revolutionizing Supply Chain Visibility

Conclusion

The Milk Run model works because it replaces reactive movement with deliberate design. By consolidating routes, stabilizing schedules, and maximizing asset use, it turns transportation into a predictable, manageable system.

For logistics operations struggling with rising costs, underutilized fleets, and daily execution pressure, the Milk Run model offers a practical way to move more freight — with fewer vehicles and fewer surprises.

Thanks For Reading: 9 Benefits of Milk Run Model in Logistics

Powered By 360Presence