Role of Artificial Intelligence in Supply Chain Optimization

Artificial Intelligence is as a discipline and subfield of computer science, which deals with the development of a model that is capable of succeeding in solving the problems that require human intelligence throughout supply chain management on its contemporary stage. Indeed the beneficial use of artificial intelligence has been observed in areas such as predictive analytics and demand forecasting to the use of self-driving cars and robotic process automation can be listed. Indeed, its aptitude to process large volumes of data, patterns & decision making in real time has made it possible for a business to squeeze efficiencies in its supply chain processes like never before.

This blog explores the role of AI in supply chain optimization, detailing its applications, benefits, and the challenges businesses may face when implementing AI technologies.

What Is Supply Chain Optimization?

Optimizing Supply chain management systems are combined methods to speed up operations and cut costs. Technologies like blockchain, IoT, and AI are key in this process. Among them, AI stands out as the most promising. It can design and implement optimized supply chain procedures, making real-time decisions and adjustments. AI enhances demand forecasting, inventory management, logistics, and more.

Supply Chain Optimization also comes with storage, shipping, server management, and job hours are among the costs associated with supply chains. Improperly managed supply chains result in more hours spent picking products, longer travel times between the product and its destination, and more computer space for storing incorrect data. Poor supply chain management can also impede quality control efforts, resulting in increased returns and disgruntled consumers.

Enhance Your Supply Chain! With AI

A Look Into AI-Driven Supply Chain

AI can improve supply chain operations at almost every level. Its prospective use cases begin in the planning stage. These tools can analyze a company’s structured and unstructured data to provide insights into inbound supplies, customer location profiles, and other topics. The AI technologies can then create a planning analytics dashboard or produce a supply chain planning document.

AI programs also aid in the execution phase, as machine-learning algorithms can assist with decisions about warehouse and inventory management, transportation management, and global trade management.

AI Technologies Transforming Supply Chain Management

Machine Learning (ML)

Machine learning algorithms analyze historical data to identify patterns and trends, improving demand forecasting, inventory management, and supply chain planning. By continuously learning from new data ML models can predict future demand and optimize stock levels reducing the risk of overstocking or stockouts.

Robotics and Automation

AI-powered robots and automated systems help in making warehouse operations efficient from picking and packing to sorting and shipping. These robots work faster and more accurately than human hence increasing efficiency and reducing labor costs. Autonomous vehicles and drones also play a important role in enhancing transportation and delivery processes.

Natural Language Processing

Natural Language Processing (NLP) technology can track both internal and external data in real time. For example, a corporation that uses a social media monitoring NLP tool could keep track of external trends, such as traffic accidents or wildfires, that could affect its transportation operations. These technologies can also help to reduce friction caused by language problems because they can be trained to collect and evaluate data in multiple languages.

Predictive Analytics

Predictive analytics uses artificial intelligence (AI) to evaluate historical and real-time data which help in identifying possible supply chain disruptions. This enables businesses to resolve issues before they escalate hence increasing overall supply chain resilience and performance. Predictive analytics can also improve routing, shorten lead times, and increase customer satisfaction by ensuring on-time deliveries.

Computer vision

Computer vision technology enables AI systems to understand and evaluate visual data obtained from cameras and sensors. Computer vision can be used in the supply chain which is helpful in improving quality control, inventory management, and monitor production lines. It can detect faults, track inventory levels, and verify that safety requirements are followed and all of which improve efficiency and accuracy.

You May Also Like to Read: Digital Transformation in Supply Chain

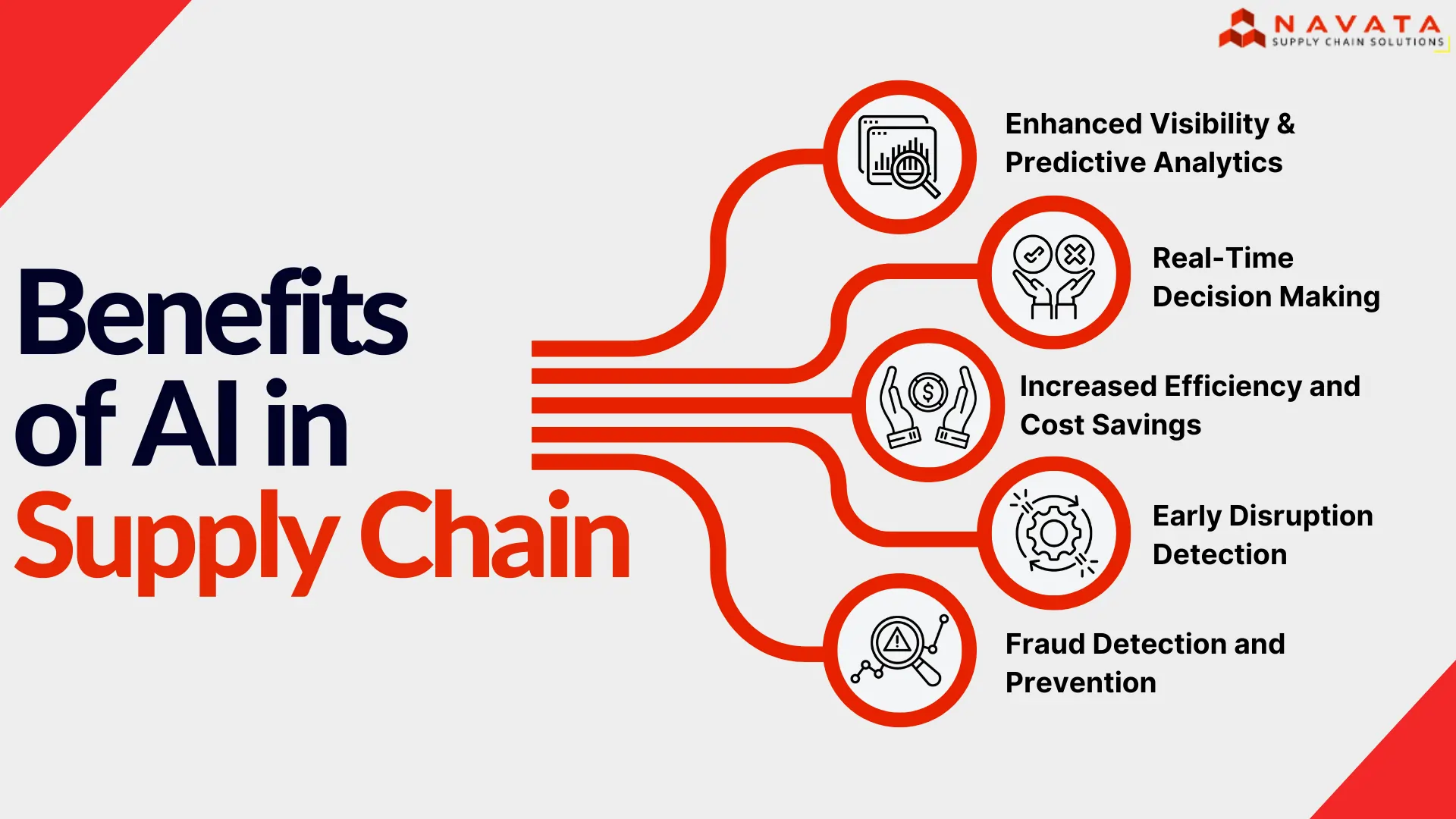

Benefits of AI in the Supply Chain

Enhanced Visibility & Predictive Analytics

AI tools can continuously monitor real-time supply chain parameters. Businesses can combine these technologies with IoT devices to track warehouse temperatures, gas mileage, and other critical information. More crucially, AI can structure these data points as they are collected and apply them to predict potential problems.

Real-Time Decision Making

When an AI tool receives supply chain data, it learns more about the company’s operations. These technologies leverage operational knowledge to discover inefficiencies and offer corrective measures. For example, an AI tool may detect a progressive increase in Hyderabad-based consumers and advise keeping more products at the warehouse nearest Hyderabad.

Increased Efficiency and Cost Savings

To do everything possible with a single AI program, a vast team of employees would be required. Even if a corporation employed such a team, they would be unable to optimize supply chain procedures at the same speed as an AI tool.

AI may be used to detect process gaps in real-time or anticipate them using unstructured data. Once these process gaps are discovered the program can offer corrective measures to improve ROI.

Early Disruption Detection

AI systems can evaluate massive volumes of data from a variety of sources, including weather reports, social media, and news sites, to forecast potential disruptions. This early identification allows businesses to proactively handle concerns such as natural disasters, political instability, and supply shortages before they disrupt the supply chain.

Fraud Detection and Prevention

AI algorithms can detect unusual patterns and anomalies in financial transactions and supply chain activities, helping to identify potential fraud or security breaches. This enables companies to take swift action to prevent losses and protect their assets.

Conclusion

Artificial intelligence (AI) is revolutionizing supply chain management by solving complex problems that require human intelligence. It excels in predictive analytics, demand forecasting, self-driving vehicles, and robotic process automation. AI’s ability to process large data sets and make real-time decisions boosts supply chain efficiency like never before. This blog has explored AI’s role in optimizing supply chains, highlighting its applications, benefits, and the challenges businesses may face when adopting AI technologies.

From improving demand forecasting and inventory management to enhancing logistics and customer satisfaction, AI is a powerful tool. However, companies must navigate challenges such as data quality, costs, skill gaps, and ethical concerns. Despite these hurdles, AI’s potential to transform supply chains makes it an essential technology for businesses aiming to stay competitive in today’s fast-paced market.

Thanks For Reading: The Role of Artificial Intelligence in Supply Chain Optimization

Powered By 360Presence

FAQ

What is AI in supply chain optimization?

AI enhances supply chain optimization by leveraging predictive analytics, demand forecasting, and real-time decision-making, leading to increased efficiency, cost savings, and improved overall performance.

What are the benefits of AI-powered robotics in warehouses?

AI-powered robots increase efficiency in warehouse operations by automating tasks like picking, packing, sorting, and shipping, which reduces labor costs and enhances accuracy and speed.

What are the main challenges of implementing AI in supply chains?

Challenges include ensuring high-quality data, managing costs and ROI, addressing skill gaps and training needs, and navigating ethical and privacy concerns.

How does AI help in fraud detection?

AI algorithms detect unusual patterns and anomalies in transactions, identifying potential fraud or security breaches, allowing companies to take swift action to protect their assets.

How does natural language processing (NLP) benefit supply chain management?

NLP tracks internal and external data in real time, helping businesses monitor trends and reduce language barriers, which can improve decision-making and operational efficiency.

3 Comments