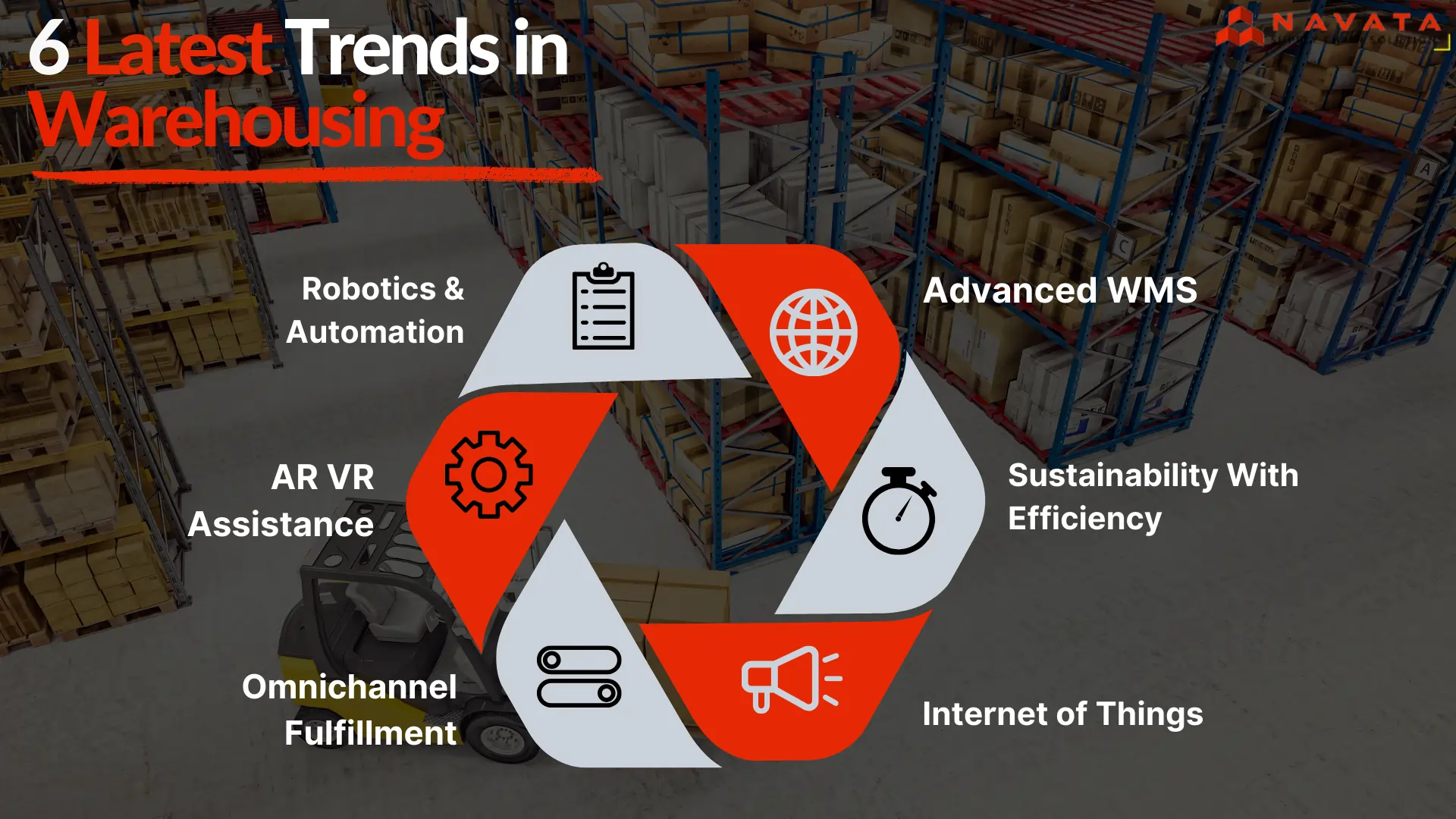

6 Latest Trends in Warehousing

Warehousing plays a backbone role within the global supply chain network. In today’s world, where technology and market demands rapidly evolve, warehouses can no longer just be static buildings for storing goods. To excel amidst rising customer expectations and complex supply chain hurdles, warehouses are becoming adaptable, hyper-efficient, and intelligent hubs. Let’s explore the forefront of warehouse trends redefining how we think about these pivotal spaces.

Automation on the Rise

Automation continues its surge in warehouse operations. This means:

Robotics Revolution: Collaborative robots (“cobots”) working alongside humans, autonomous mobile robots (AMRs), automated guided vehicles (AGVs), and picking robots streamline order fulfillment. They increase accuracy, reduce labor costs, and improve workflow efficiency.

Material Handling Automation: Automated equipment such as conveyors, sorters, and AS/RS (Automatic Storage and Retrieval Systems) expedite moving and storing goods. This cuts processing time and optimizes space utilization.

You Might Also Like To Read: Warehouse Cost Reduction: 6 Practical Tips and Techniques

Warehouse Management Systems (WMS)

Warehouse Management Systems (WMS) have long been instrumental, but advancements make them even more integral. Here’s why:

Cloud-Based Evolution: SaaS (Software as a Service) models bring greater scalability and accessibility to WMS solutions. Cloud connectivity opens real-time data collaboration and enables smaller businesses to adopt robust features without massive hardware investments.

Data-Driven Decision Making: Advanced WMS systems capture a wealth of data. The power of big data analytics offers warehouse managers unprecedented insights to optimize everything from inventory placement and labor assignments to picking routes and forecasting models.

Focus on Sustainability

Sustainability and ESG (Environmental, Social, and Governance) concerns are becoming core principles for businesses globally. Warehouses are taking steps toward going green:

Energy Efficient Choices: Energy management systems, natural lighting with adaptive controls, and solar panels all contribute to reduced energy consumption and a lower carbon footprint.

Sustainable Packaging: Warehouses collaborate with suppliers on eco-friendly packaging solutions that minimize waste and utilize recyclable materials.

Waste Reduction: Smart WMS software helps optimize routes and inventory placement, in turn reducing unnecessary product movement and minimizing warehouse waste.

Optimize Your Operations: Explore Our Warehousing Solutions

IoT and the Connected Warehouse

The Internet of Things (IoT) has embedded itself across industries, and warehouses are no exception. These applications enhance operations:

Real-time Tracking: IoT sensors on packages, equipment, and vehicles generate real-time location data, improving inventory visibility and enabling better asset management.

Condition Monitoring: IoT-equipped smart storage containers send temperature and humidity alerts for perishable goods, minimizing spoilage and improving quality control

Predictive Maintenance: IoT helps detect early signs of wear on equipment, allowing preventive maintenance scheduling. This prevents unexpected downtime and ensures machinery runs optimally.

Omnichannel Fulfillment

Warehouses no longer simply cater to pallets of bulk orders for brick-and-mortar stores. Omnichannel retail is the new standard, driving a need for dynamic warehouses. This entails:

Micro-fulfillment Centers: Located closer to end consumers (sometimes even within retail locations), these “mini warehouses” facilitate speedy order fulfillment, essential for last-mile delivery and buy-online-pickup-in-store (BOPIS) models.

Adaptable Infrastructure: Warehouses are designed (or retrofitted) for easy reconfiguration as business needs shift. Modular warehouse solutions allow for adaptable fulfillment strategies as e-commerce surges or B2B requirements evolve.

Embracing Immersive Reality

Augmented Reality (AR) and Virtual Reality (VR) are making their mark on warehouses, transforming how operations function:

AR-Assisted Picking: AR glasses overlay data like product locations and quantities on a worker’s view, streamlining the picking process and drastically reducing errors.

VR Training: Virtual reality simulates safe work environments to train and upskill employees on operating specialized equipment or learning warehouse procedures. This is ideal for onboarding and reducing the risks and expenses of real-world training.

Layout Optimization: VR aids in designing and virtually testing new warehouse layouts before implementation, allowing for data-driven decisions on improving workflow.

Conclusion

Warehouses are no longer just places to store stuff. They’re evolving into incredibly high-tech and adaptable hubs that are essential for how we shop and how businesses operate. Here’s what we’ve seen with the trends explored:

Robots and Automation: We have robots on wheels, robotic arms, smart conveyors – all making picking, packing, and moving stuff incredibly fast and accurate.

Brain Power (Software): Warehouse management systems are like the super-smart brains controlling everything. They make decisions based on a ton of data to keep things efficient and help businesses improve over time.

Going Green: Warehouses are using new tech for less energy waste, smarter packaging that’s better for the planet, and being really careful about minimizing waste.

Connected Everything: Think sensors galore! They track where every package and forklift is, check the temperature for important deliveries, and even tell us when machines need a tune-up before they break down.

Ready for Anything: No more warehouses set up for “just one thing”. Everything is getting rethought to handle online orders, store pickups, big store shipments – with things shifting quickly as people’s shopping habits change.

All these trends are happening to keep up with how we are shopping. We want things faster, whether it’s from a website or the store down the street. We also care about companies acting responsibly towards the environment. Warehouses are changing with this – it’s pretty exciting to see what they’ll come up with next!

Thanks For Reading: 6 Latest Trends in Warehousing

Powered By 360Presence

1 Comment