What Is Milk Run Model in Logistics?

At its core, the Milk Run model is a multi-stop transportation strategy where a single vehicle follows a fixed route to collect or deliver goods at multiple locations before returning to a hub.

Instead of treating each shipment independently, logistics teams consolidate volumes across locations and time windows. Routes are planned based on geography, demand consistency, vehicle capacity, and service commitments — not on one-off shipment requests.

The result is a transportation system that prioritizes predictability and asset efficiency over ad-hoc movement.

You May Also Like to Read: What Is Reverse Logistics?

How Milk Run Model Works?

Milk Run routes are pre-defined and executed on fixed schedules — daily, alternate-day, or weekly depending on demand patterns.

Each stop on the route has a defined loading or unloading window, allowing warehouses, suppliers, and drivers to coordinate efficiently. Vehicles are sequenced to minimize backtracking and idle time, ensuring that capacity is utilized across most of the route.

Technology plays a critical role here. Route planning tools and TMS platforms help design routes, monitor adherence, and make controlled adjustments when exceptions occur.

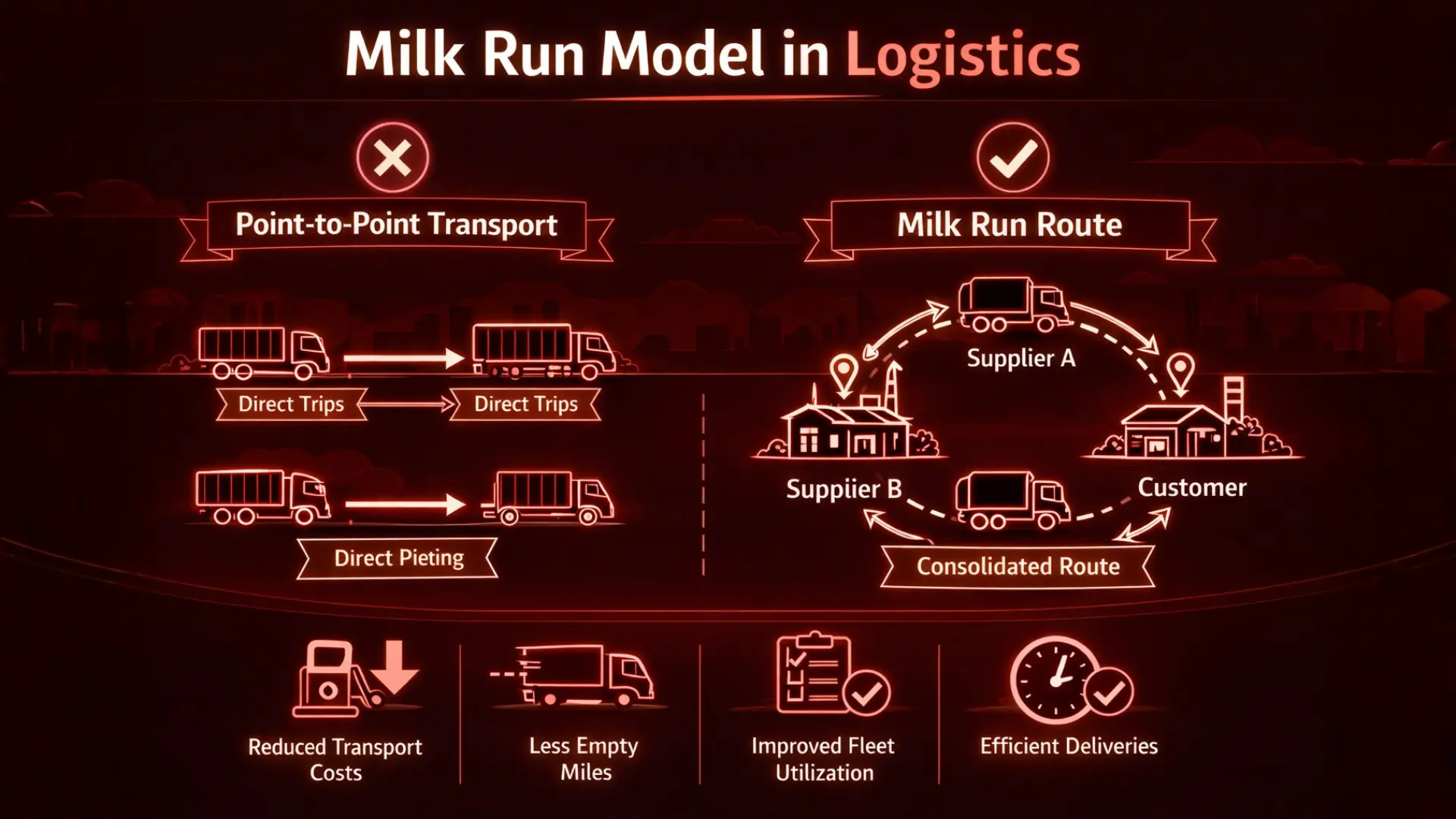

Why Traditional Point-to-Point Transport Creates Waste?

Point-to-point transportation works when shipment volumes are large and urgent. However, for fragmented or recurring movements, it introduces structural inefficiencies.

Vehicles often:

run under capacity

return empty after single deliveries

require frequent dispatch planning

This drives up cost per shipment and reduces fleet productivity. The Milk Run model solves this by aggregating demand, not increasing dispatch frequency.

How the Milk Run Model Reduces Transport Costs?

The cost advantage of Milk Runs comes from systematic consolidation, not speed.

Multiple stops are served in a single trip

Empty miles reduce significantly

Fuel, driver, and toll costs are spread across shipments

Because routes are planned in advance, emergency or premium freight usage declines. Over time, transport spend becomes more stable and easier to control.

How Fleet Utilization Improves with Milk Runs

Fleet utilization improves when vehicles operate closer to their optimal capacity for longer durations.

Milk Run routes are designed to balance load volumes across stops, reducing both underfilled and overloaded trips. Fixed schedules also reduce idle vehicle time and improve driver shift planning.

For fleet managers, this leads to:

better asset productivity

clearer capacity planning

improved maintenance scheduling

Utilization becomes intentional rather than incidental.

Operational Benefits Beyond Cost Savings

Milk Run models improve more than just transport economics.

Predictable arrivals stabilize warehouse operations. Dock congestion reduces because inbound and outbound flows are planned. Inventory replenishment becomes rhythm-based rather than reactive.

This consistency directly supports:

higher OTIF performance

improved SLA adherence

smoother coordination across logistics partners

Transportation stops being a daily firefighting function and becomes a controlled capability.

Read More About: 13 Effective Inventory Management Strategies

Where Milk Run Model Works Best?

The Milk Run model delivers the highest value in networks with:

multiple suppliers or delivery points within a defined geography

consistent, repeatable shipment volumes

structured time windows

Common applications include manufacturing inbound logistics, retail store replenishment, FMCG distribution, and B2B multi-drop delivery networks.

It is less effective for irregular, long-haul, or one-time shipments where route stability cannot be maintained.

Technology as the Backbone of Milk Run Execution

Without technology, Milk Runs quickly lose efficiency.

TMS platforms enable route design, load planning, cost tracking, and performance measurement. GPS tracking and telematics ensure visibility and accountability during execution.

Analytics help refine routes continuously — adjusting stop sequences, frequency, and capacity based on real demand patterns.

Implementation Challenges to Plan For

Milk Runs require discipline. Poor demand forecasting can lead to imbalanced routes. Delays at one stop can cascade across the entire route.

Successful implementation depends on:

accurate volume forecasting

standardized loading processes

strong coordination across all stops

clear exception-handling protocols

When these controls are missing, Milk Runs lose their advantage.

Milk Run vs Direct Transport: A Practical View

Direct transport offers flexibility and speed for urgent or high-volume shipments. Milk Runs offer efficiency and predictability for recurring movements.

Most mature logistics networks adopt a hybrid approach — Milk Runs for stable flows, direct transport for exceptions.

The choice is not either-or; it is situational.

Read More About: Role of Skilled Workers in Successful Supply Chain

Conclusion

The Milk Run model is not a shortcut — it is an operational design choice. When executed with planning discipline and system support, it reduces transport costs, improves fleet utilization, and stabilizes logistics execution.

For organizations under pressure from rising freight costs and asset inefficiency, the Milk Run model provides a structured path to move more freight with fewer vehicles — consistently and predictably.

Thanks For Reading: Milk Run Model in Logistics: How It Reduces Transport Costs and Improves Fleet Utilization

Powered By 360Presence