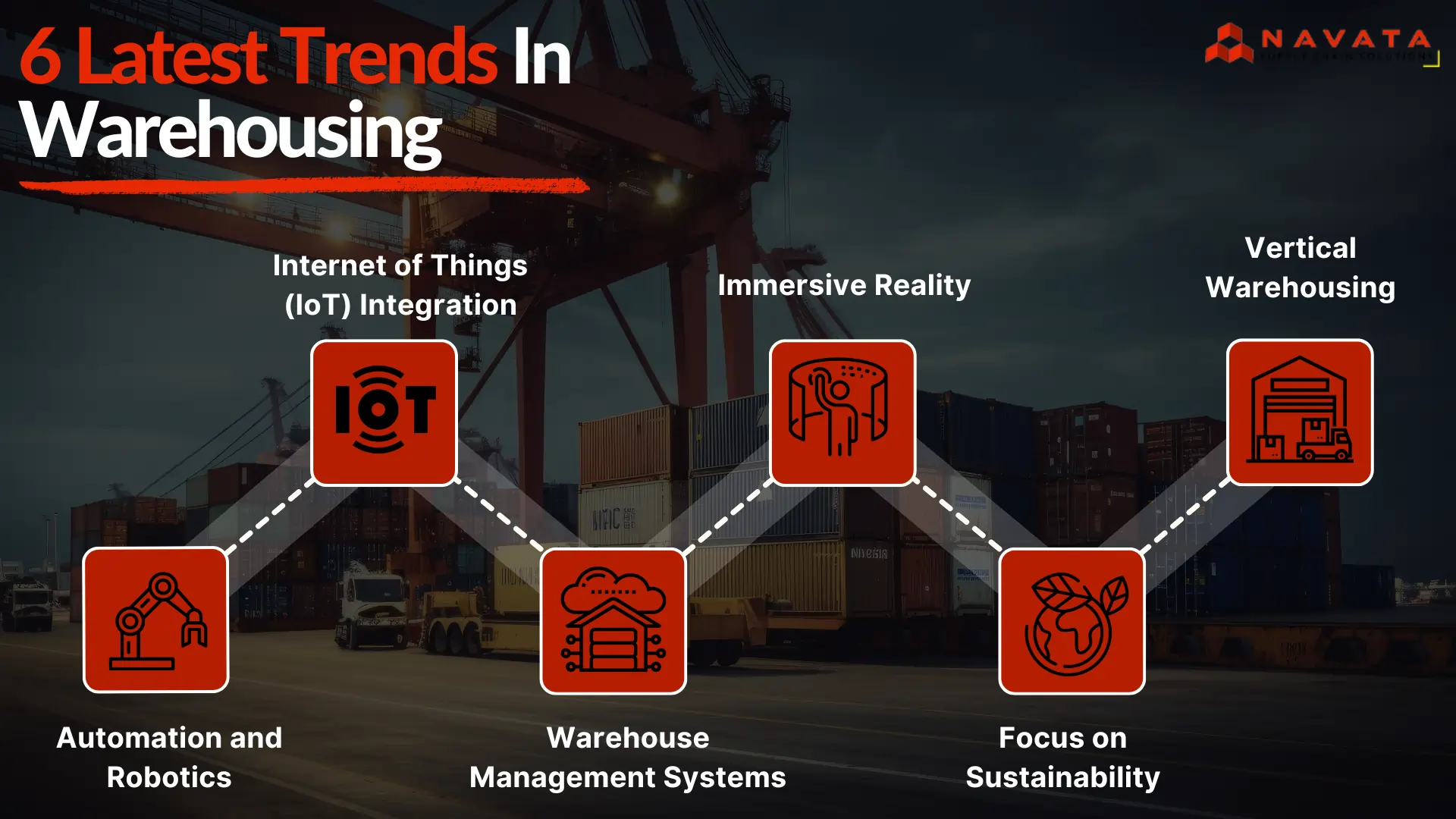

6 Latest Trends In Warehousing

Warehouses have always played a crucial part in getting things to customers. But today, they’re not just places to store stuff – they’re high-tech hubs that make fast shipping and happy customers possible. Let’s dive into the exciting trends turning warehouses into powerhouses of efficiency:

Automation and Robotics

Automation has revolutionized the warehousing industry, making processes more efficient and less labor-intensive. One of the most significant advancements in this area is the integration of robotics into warehouse operations. Robots are now capable of performing a wide range of tasks, including picking and packing, inventory management, and even autonomous material movement.

These robots are equipped with sensors and artificial intelligence algorithms, allowing them to navigate through the warehouse environment safely and efficiently. By automating repetitive tasks, businesses can increase productivity, reduce errors, and lower operational costs.

Robots are changing warehousing big time! Here’s how:

Speedy Sorting: Sorting robots can scan items way faster than humans, moving boxes and packages to the right places quickly.

Perfect Picking: Robots are programmed to be error-free pickers. They locate items, grab them carefully, and get those orders packed right.

Moving Muscle: Robots haul heavy bins, pallets, and more. This frees up human workers for tasks that need extra attention.

Team Players: Cobots, or collaborative robots, are designed to work alongside humans, lending an extra hand (or gripper!) wherever needed.

Internet of Things (IoT) Integration

The Internet of Things (IoT) is another technology that is transforming the warehousing landscape. IoT devices such as sensors and RFID tags can be used to track the movement of goods throughout the warehouse in real-time. This provides warehouse managers with valuable insights into inventory levels, storage conditions, and asset location.

By harnessing the power of IoT, warehouses can optimize their operations, improve inventory accuracy, and enhance overall efficiency. For example, IoT sensors can alert staff to potential issues such as temperature fluctuations or equipment malfunctions, allowing them to take corrective action before problems escalate.

IoT means connecting everyday objects to the internet. In warehouses, this looks like:

Smart Sensors: Sensors on everything from forklift trucks to storage shelves let you track equipment status, see where items are, and even get alerts when temperatures or humidity change in sensitive areas.

Predictive Maintenance: IoT sensors can tell you when a machine is about to need maintenance, preventing unexpected breakdowns that disrupt operations.

Real-Time Alerts: Get notified about potential delays, security issues, and more. This allows you to address problems before they become major headaches.

Warehouse Management Systems (WMS)

While not a new technology, Warehouse Management Systems (WMS) are evolving rapidly and remain the backbone of smart warehouses. They provide real-time inventory visibility, optimize operations, and drive data-driven decision-making. Here’s why they are even more crucial:

SaaS and the Cloud: Cloud-based WMS delivered via Software-as-a-Service (SaaS) models bring scalability and cost-effectiveness to businesses of all sizes. Real-time data access and collaboration are a click away with cloud deployment.

The Power of Big Data Analytics: Advanced WMS don’t just manage; they generate insights. Big data analytics help optimize warehouse layouts, labor scheduling, picking routes, shipment planning, and more, creating a leaner, smarter facility.

Immersive Reality

Augmented Reality (AR) and Virtual Reality (VR) are moving warehouses beyond traditional training methods and operational tools:

Virtual Training and Simulation: Immersive technologies train warehouse staff on complex procedures with minimal risk, allowing practice in realistic environments before working with actual inventory.

AR-Powered Picking: AR glasses overlay picking instructions and location information, increasing picking accuracy and efficiency while reducing paper-based guides.

Remote Support and Troubleshooting: AR/VR enable remote experts to assist technicians on-site, visually guiding them through equipment repairs or complex problem-solving.

Focus on Sustainability

In recent years, there has been a growing focus on sustainability within the warehousing industry. With increasing awareness of environmental issues such as climate change and resource depletion, many warehouses are implementing sustainable practices to reduce their carbon footprint and minimize waste.

Consumer and regulatory demands for eco-conscious supply chains are transforming warehouse operations. Sustainability is a vital trend driving warehouse innovation:

Energy Efficiency: From solar panels to energy-efficient lighting and heating/cooling systems, warehouses are reducing their carbon footprint.

Recycled and Sustainable Materials: Warehouse construction, packaging, and shipping materials are increasingly prioritizing recycled content and sustainable choices.

Route Optimization: Through data analysis and advanced algorithms, WMS systems help reduce transportation miles and minimize the environmental impact of last-mile delivery.

Vertical Warehousing

As urbanization continues to increase, warehouse space in densely populated areas is becoming scarce and expensive. To address this challenge, many warehouses are now adopting a vertical layout, utilizing tall storage systems and automated picking technologies to make the most of limited space.

Vertical warehousing allows businesses to maximize their storage capacity without expanding horizontally, reducing their footprint and lowering operating costs. By stacking inventory vertically, warehouses can store more goods in the same amount of floor space, making it easier to fulfill orders quickly and efficiently.

Thanks For Reading: 6 Latest Trends In Warehousing

Powered By 360Presence

FAQ

What is the role of robots in warehousing?

Robots enhance warehousing by speeding up sorting, ensuring error-free picking, moving heavy items, and working collaboratively with humans. They automate repetitive tasks, increasing productivity, reducing errors, and lowering operational costs.

What are the benefits of Augmented Reality (AR) in warehouses?

AR enhances picking accuracy and efficiency by overlaying instructions on AR glasses. It also improves training with virtual simulations and allows remote specialists to visually help on-site personnel, lowering errors and downtime.

What is vertical warehousing?

Vertical warehousing utilizes tall storage systems and automated technologies to maximize limited space. It allows more goods to be stored in the same floor space, improving storage capacity and operational efficiency.

What are the benefits of cloud-based Warehouse Management Systems (WMS)?

Cloud-based WMS offer scalability, cost-effectiveness, and real-time data access. They enable collaboration across various locations and provide advanced analytics to optimize warehouse operations and improve decision-making.

What VR in warehouse?

VR provides realistic training simulations for warehouse staff, allowing them to practice procedures safely. It also enables remote experts to assist on-site technicians visually, guiding them through complex repairs and problem-solving.