What is Inventory Management?

Inventory management refers to the systematic process of ordering, storing, tracking, and utilizing a company’s goods. It encompasses everything from raw materials to finished products, ensuring the right items are available at the right time, in the right quantities, and at optimal costs. The goal is to minimize waste, reduce storage expenses, and prevent stockouts or overstocking.

Key elements of inventory management systems include:

Demand forecasting

Precisely predicting customer needs allows businesses to align stock levels, minimizing overstocking and preventing shortages, thus optimizing inventory costs and ensuring product availability.

Stock replenishment

Timely and accurate reordering of inventory is crucial to avoid stockouts, maintain continuous product availability, and prevent disruptions in the supply chain, ensuring customer satisfaction.

Inventory tracking

Employing tools like barcodes or RFID provides real-time visibility into stock levels, enabling accurate monitoring, reducing errors, and facilitating efficient management of goods throughout the warehouse.

Warehouse organization

Efficiently storing products through optimized layouts and systematic placement ensures quick access, reduces picking times, minimizes operational costs, and improves overall warehouse productivity and flow.

By mastering these components, businesses can achieve supply chain management efficiency and improve profitability.

You May Also Like to Read: E-commerce Inventory Management

Types of Inventory Management System

Businesses can choose from several strategies based on their needs:

1. Perpetual Inventory System

This system tracks inventory levels in real-time using inventory management software or technology like RFID tags. It offers continuous visibility into stock, minimizes stockouts, and reduces carrying costs by ensuring accurate, up-to-date data.

2. Periodic Inventory System

Unlike perpetual, this system relies on infrequent physical counts at fixed intervals, such as monthly or quarterly. While less accurate and labor-intensive due to its manual nature, it proves a cost-effective solution for smaller businesses with manageable inventory volumes.

3. Just-in-Time (JIT) Inventory

Popularized by Toyota, JIT focuses on receiving materials and producing goods only as needed. It requires tight collaboration with suppliers to minimize storage costs and waste, though it demands precise demand forecasting.

4. Materials Requirement Planning (MRP)

MRP is a system that uses production schedules and existing inventory data to precisely determine the necessary quantities of raw materials and components. Aligning procurement with production timelines ensures materials are available exactly when needed, effectively preventing costly manufacturing delays and optimizing resource allocation.

5. ABC Analysis

ABC Inventory method categorizes inventory into three groups based on value: ‘A’ for high-value items needing strict control, ‘B’ for moderate-value items, and ‘C’ for low-value, high-volume items. This strategic prioritization of resources enables businesses to achieve optimal stock optimization and efficient management.

6. First-In, First-Out (FIFO):

This inventory management principle ensures that the oldest stock in inventory is sold or used before newer stock. FIFO is particularly critical for businesses dealing with perishable goods, such as food or pharmaceuticals, as it minimizes spoilage, obsolescence, and maintains product freshness for consumers.

7. Economic Order Quantity (EOQ)

EOQ is a mathematical model used to determine the optimal order quantity that minimizes the total cost of inventory. It balances the costs associated with placing orders and the costs of holding inventory, helping businesses achieve significant savings.

8. Days Sales of Inventory (DSI)

While not a management system, DSI is a crucial metric measuring the average number of days it takes for a company to convert its inventory into sales. A lower DSI indicates faster inventory turnover, reflecting greater operational efficiency and strong sales performance.

9. Manual Inventory

This basic approach involves tracking inventory using simple tools like spreadsheets or paper records. Although prone to human error and highly inefficient as operations scale, it remains suitable for very small businesses with extremely limited inventory and simple needs.

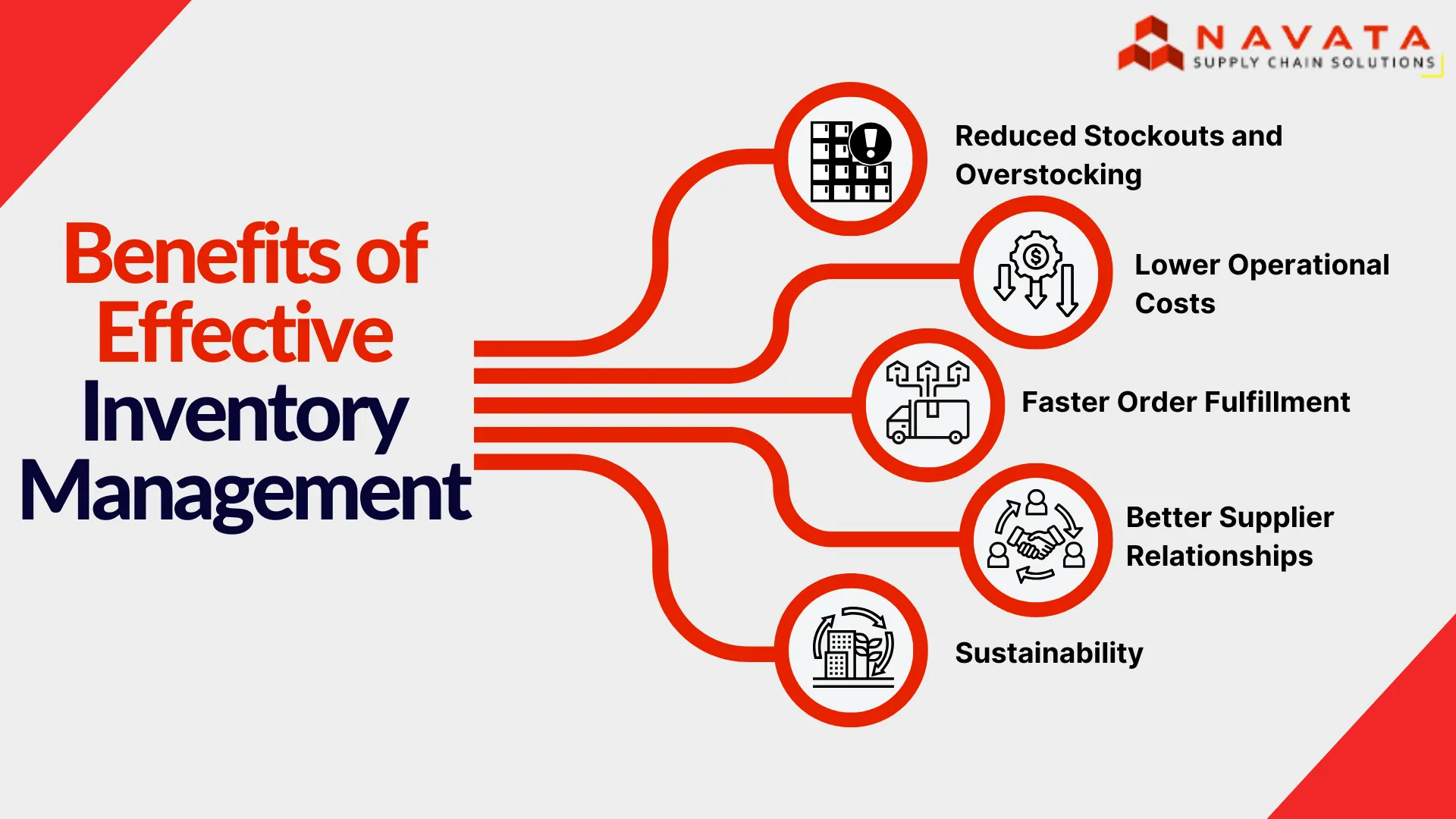

Benefits of Inventory Management System

Implementing robust inventory control practices offers tangible advantages:

Reduced Stockouts and Overstocking

Real-time tracking tools, like RFID tags or barcode scanners, provide precise visibility into current stock levels. This proactive insight prevents costly imbalances, ensuring businesses avoid both frustrating stockouts and expensive overstocking, optimizing inventory flow.

Lower Operational Costs

Optimized inventory management significantly reduces various operational expenses. This includes decreased warehousing fees due to less stored goods, lower insurance premiums for reduced inventory value, and minimized labor costs associated with managing excessive stock.

Faster Order Fulfillment

Well-organized warehouses combined with accurate inventory tracking systems dramatically speed up the entire order fulfillment process. Efficient picking and shipping procedures result in quicker delivery times, significantly boosting customer satisfaction and operational efficiency.

Better Supplier Relationships

Implementing timely reordering based on precise inventory data and maintaining clear communication fosters stronger supplier relationship. Reliable forecasting and consistent interaction lead to more favorable terms, better pricing, and improved overall supplier collaboration.

Sustainability

Effective inventory management contributes directly to more eco-friendly operations. By minimizing waste, reducing excess stock, and optimizing transportation, businesses can significantly lower their environmental footprint, promoting a more sustainable and responsible supply chain practice.

Read More About: 8 Benefits of Just-in-Time Inventory Technique

Why Is Inventory Management Important?

Effective inventory control directly impacts a company’s bottom line. Here’s why it matters:

Cost Reduction

Proper stock optimization eliminates excess inventory, significantly reducing capital tied up and decreasing storage, spoilage, and obsolescence expenses, leading to substantial savings for the business.

Improved Cash Flow

Maintaining lean inventory levels frees up valuable capital. This allows businesses to allocate funds to critical areas like marketing, research and development, or other strategic investments, enhancing financial flexibility.

Enhanced Customer Satisfaction

Avoiding stockouts ensures timely order fulfillment and consistent product availability. This reliability significantly boosts customer trust, fosters loyalty, and drives strong long-term customer retention for the business.

Data-Driven Decisions

Modern inventory management software provides critical analytics. These insights enable businesses to identify trends, optimize reorder points, forecast demand accurately, and continuously streamline overall supply chain operations for efficiency.

Scalability

Automated inventory management systems facilitate seamless expansion as businesses grow. They ensure efficient supply chain operations can scale without manual errors, supporting increased volume and complexity effortlessly.

Optimize Your Stock. Maximize Your Profit Now!

Conclusion

Inventory management is not just a logistical task—it’s a strategic advantage. By understanding what inventory management is, adopting the right tools, and implementing best practices, businesses can reduce costs, satisfy customers, and scale efficiently.

Start by auditing your current processes, invest in inventory management software, and train your team to embrace data-driven decisions. With these steps, you’ll be well on your way to dominating search engine rankings and your industry.

Thanks For Reading: What is Inventory Management? Types, Benefits & Importance

Powered By 360Presence

4 Comments