Orchestration vs Optimization in Supply Chains

In modern supply chains, the terms orchestration and optimization are often used interchangeably. Both aim to improve performance, reduce cost, and enhance efficiency. Yet they operate at fundamentally different levels of the system.

Optimization improves how individual components perform.

Orchestration determines how those components work together.

As supply chains expand across suppliers, manufacturing sites, fulfillment centers, and markets, understanding this difference becomes critical. Many organizations focus heavily on optimization and assume systemic improvement will follow. In reality, without orchestration, optimization can create misalignment across the network.

You May Also Like to Read: What is Supply Chain Visibility?

What Is Supply Chain Optimization?

Supply chain optimization refers to improving performance within a defined function or process. It focuses on achieving the best possible outcome under specific constraints such as cost, time, service levels, or capacity.

Optimization is typically applied to areas such as:

Transportation routing and load planning

Warehouse productivity and slotting strategies

Inventory level adjustments

Production scheduling efficiency

Procurement cost reduction

Each initiative aims to maximize efficiency within a local boundary. The logic is mathematical and performance-driven: reduce cost per unit, increase throughput, improve utilization.

In contained or relatively simple supply chains, these improvements often translate directly into overall gains. However, optimization assumes that improvements in one area will not destabilize another — an assumption that becomes fragile in complex networks.

What Is Supply Chain Orchestration?

Supply chain orchestration operates at a higher, structural level. Instead of improving isolated activities, orchestration aligns sourcing, production, inventory, and distribution decisions across the entire network.

Orchestration ensures that:

Procurement strategies support production stability

Production planning aligns with inventory positioning

Inventory strategy supports service commitments

Distribution flow reflects demand variability

Rather than asking how to make a single function more efficient, orchestration asks how the entire supply chain should behave as an integrated system.

This requires synchronized planning cycles, shared performance metrics, unified visibility, and clear governance over cross-functional trade-offs.

Where optimization focuses on performance metrics, orchestration focuses on system alignment.

Key Differences Between Orchestration and Optimization in Supply Chains

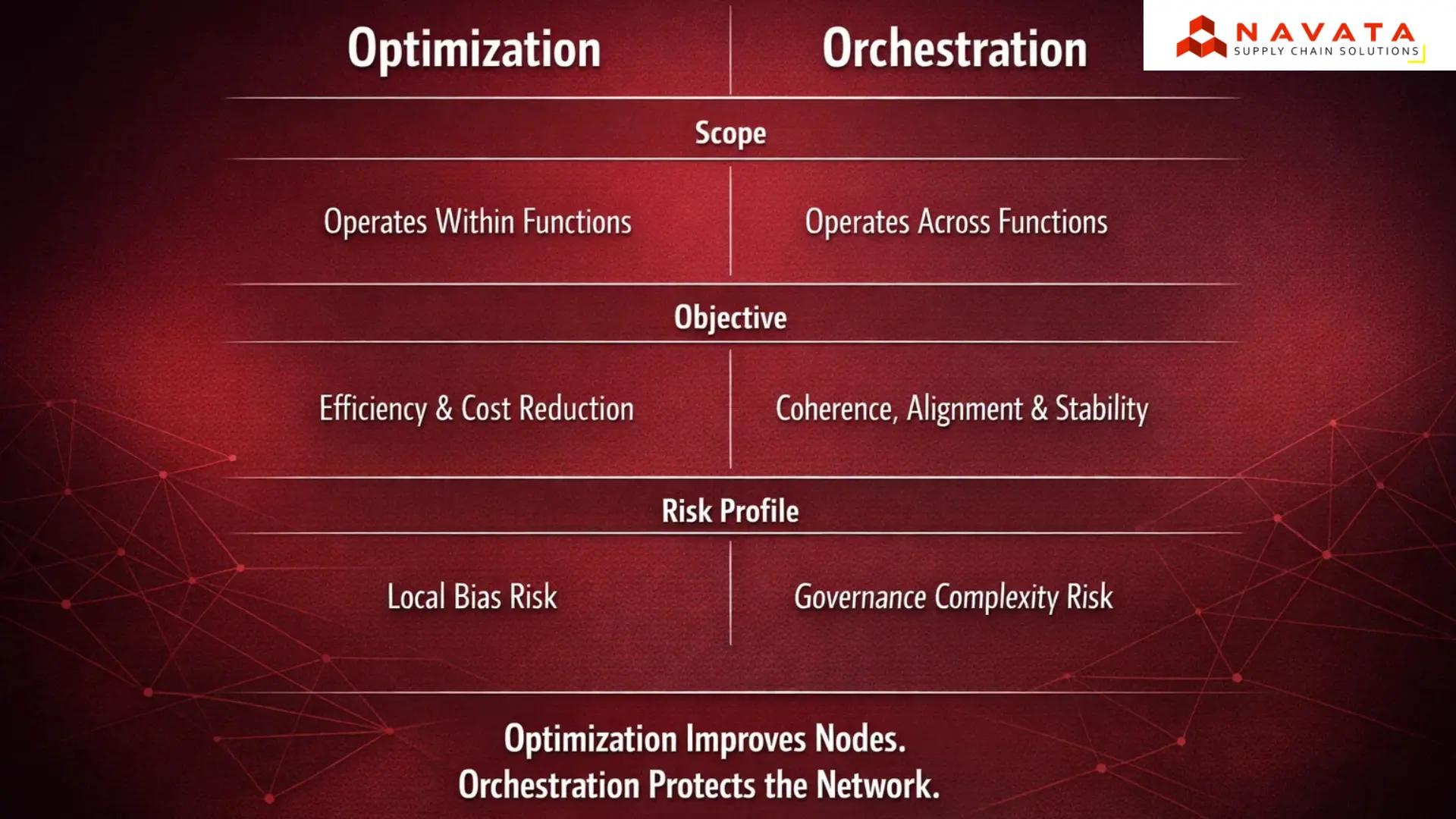

The distinction between orchestration and optimization can be understood across three structural dimensions: scope, objective, and risk.

Scope:

Optimization operates within functions. Orchestration operates across functions.

Objective:

Optimization seeks efficiency and cost reduction. Orchestration seeks coherence, alignment, and stability.

Risk Profile:

Optimization risks local bias — improving one area while unintentionally harming another. Orchestration risks slower decision-making if governance is weak, but protects the system from fragmentation.

An optimized warehouse may reduce picking time, yet create dispatch congestion if transportation schedules are not synchronized. A sourcing strategy that lowers cost may increase variability and disrupt production flow. These are not failures of optimization itself, but consequences of absent orchestration.

Optimization improves nodes.

Orchestration protects the network.

When Is Optimization Enough in a Supply Chain?

Optimization is often sufficient in supply chains that are:

Geographically concentrated

Limited in partner complexity

Operating in relatively stable demand environments

Structured with short decision pathways

In such systems, functional improvements tend to scale without creating significant cross-functional conflict. The interdependencies remain manageable, and local efficiency gains translate into systemic improvement.

For small or mid-scale operations, targeted optimization initiatives can drive meaningful performance improvement without requiring a formal orchestration layer.

You May Also Like to Read: What Is Execution Variance in Supply Chain? Cause & Impact!

When Does a Supply Chain Require Orchestration?

As supply chains grow in size and complexity, interdependencies increase. Multiple suppliers, contract manufacturers, regional distribution centers, and omnichannel fulfillment models create dense connections across functions.

At this stage, local optimization may begin to generate unintended consequences:

Aggressively reducing inventory may increase stockout risk elsewhere.

Maximizing asset utilization may reduce flexibility during demand volatility.

Lowering freight frequency may stretch lead times and inflate working capital exposure.

When cross-functional trade-offs become frequent and systemic alignment becomes difficult to maintain, orchestration shifts from optional to necessary.

Supply chains require orchestration when coordination, not execution, becomes the primary challenge.

Orchestration vs Optimization: Which Should Come First?

Framing orchestration vs optimization as a choice can be misleading. Mature supply chains require both. The question is sequencing.

Orchestration should define how the system behaves. Optimization should refine performance within that aligned structure.

Without orchestration, optimization can amplify imbalance. Local efficiency improvements may conflict with broader network objectives. With orchestration in place, optimization strengthens rather than destabilizes the system.

In other words, orchestration establishes the architecture. Optimization enhances the performance inside it.

Why Modern Supply Chains Need Both Orchestration and Optimization?

In volatile and globally distributed supply chains, resilience increasingly depends on alignment. Efficiency alone is insufficient if the system lacks coherence.

Organizations that build orchestration capabilities — unified visibility, aligned KPIs, structured governance, and synchronized planning — create stable operating foundations. Within those foundations, optimization becomes sustainable and cumulative rather than temporary.

The most competitive supply chains are not those that optimize isolated functions most aggressively. They are those that design for orchestration first and deploy optimization strategically within that coordinated framework.

Conclusion

Orchestration and optimization serve different but complementary roles in supply chain management.

Optimization enhances functional efficiency within defined boundaries. Orchestration ensures those functions operate in alignment across the entire network.

As complexity increases, systemic coherence becomes more valuable than isolated efficiency gains. The supply chains that sustain performance over time are not merely optimized — they are orchestrated, and then optimized within that structure.

Thanks For Reading: Orchestration vs Optimization in Supply Chains: What’s the Difference?

Powered By 360Presence