Definition of Execution Variance in Supply Chain

Execution variance in supply chain management is the measurable deviation between planned supply chain performance and actual execution across sourcing, production, inventory, transportation, and distribution.

It reflects how consistently the supply chain operates against its designed targets — including service levels, lead times, cost structures, and capacity utilization.

In simple terms, execution variance measures how far real performance drifts from planned intent across the entire supply chain system.

You May Also Like To Read: Process of Supplier Relationship Management

Where Execution Variance Occurs in the Supply Chain?

Execution variance can occur at any stage where planning assumptions meet operational reality. It may appear when supplier lead times exceed expectations, when production output differs from forecast, when inventory replenishment cycles stretch beyond schedule, or when fulfillment performance falls short of target service levels.

The issue is not isolated to a single function. It emerges at the intersections between functions — where procurement connects to manufacturing, where manufacturing connects to distribution, and where demand planning connects to fulfillment.

Supply chain variance is therefore systemic, not functional.

Why Execution Variance Happens?

Supply chains operations are based on coordinated plans. Forecasts drive procurement. Procurement feeds production. Production informs inventory positioning. Inventory supports distribution.

Execution variance arises when synchronization weakens.

Common structural drivers include:

Demand volatility disrupting planned production cycles

Supplier performance inconsistency

Capacity constraints within manufacturing

Information latency between planning and execution systems

Misalignment between functional KPIs

Even if each function meets its local targets, cross-functional misalignment can still generate system-level deviation.

Execution variance is often less about failure and more about coordination gaps.

How Execution Variance Is Measured?

Execution variance is measured by comparing planned KPIs with actual performance metrics across the supply chain.

Typical comparison areas include:

Planned vs actual lead time

Forecasted vs actual output

Target vs achieved service level

Planned vs actual inventory turnover

Budgeted vs realized supply chain cost

The frequency and magnitude of these deviations determine the overall stability of the supply chain.

Organizations that measure variance continuously gain visibility into structural weak points before they escalate.

Execution Variance vs Planning Variance

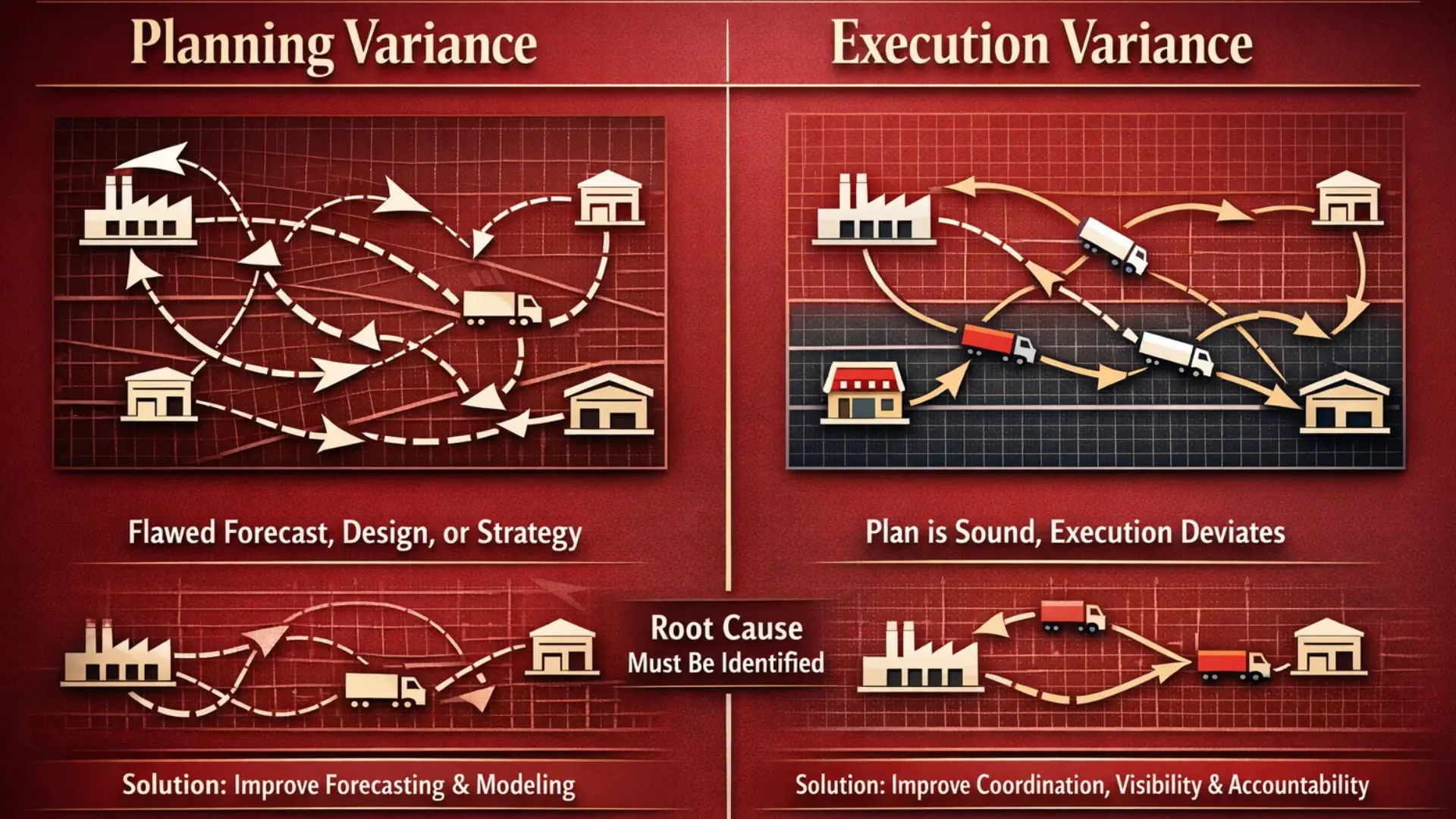

Execution variance must be distinguished from planning variance.

Planning variance occurs when the forecast, network design, or sourcing strategy is flawed from the outset.

Execution variance occurs when the plan is sound, but operational performance fails to align with it.

The distinction is critical. If planning is inaccurate, the solution lies in better forecasting and modeling. If execution is inconsistent, the solution lies in improving coordination, visibility, and accountability.

Without this separation, organizations often treat symptoms rather than root causes.

The Strategic Impact of Execution Variance

Execution variance directly affects predictability — and predictability underpins supply chain performance.

When variance increases:

Inventory buffers expand

Working capital exposure rises

Production schedules require frequent adjustment

Customer service reliability declines

Cost structures become unstable

Over time, the supply chain compensates by adding protective layers such as excess capacity or higher safety stock, increasing structural cost.

Managing execution variance therefore becomes a strategic priority, not just an operational improvement initiative.

Optimize Your Supply Chain with Experts!

Conclusion

Execution variance in supply chain management is the measurable gap between planned design and actual performance across the entire supply chain network.

While some deviation is inevitable in dynamic environments, persistent execution variance signals structural misalignment between planning and execution.

High-performing supply chains do not eliminate variance entirely. They control it, measure it, and reduce unpredictable deviations to maintain stability at scale.

In supply chain maturity, consistency is the real competitive advantage.

Thanks For Reading: What Is Execution Variance in Supply Chain? Cause & Impact!

Powered By 360Presence