What is Landed Cost?

In supply chain management, one of the most persistent cost blind spots is assuming that the purchase price of a product reflects its true cost. It doesn’t.

The real cost of a product only becomes visible once it reaches its final destination—ready for sale, production, or distribution. That all-in cost is known as landed cost.

Landed cost is not a theoretical metric or an accounting afterthought. It is the number that determines whether sourcing decisions actually scale, whether pricing holds under volume, and whether logistics efficiency improves or silently erodes margins over time.

Understanding Landed Cost Beyond the Invoice Price

At its core, landed cost represents the total cost incurred to move goods from the supplier’s gate to the point where the business can actually use or sell them. This includes not only visible charges like freight and duties, but also less obvious operational costs that accumulate across the supply chain.

From an operational standpoint, landed cost answers a single, non-negotiable question:

What does this unit truly cost the business once it is physically available and usable—not when it is ordered?

This distinction matters because most supply chain decisions—pricing, replenishment, network design, supplier selection—are made before the product arrives. If those decisions rely on incomplete cost signals, inefficiencies scale with volume. That is why landed cost sits at the intersection of procurement, logistics, warehousing, compliance, and finance. A gap in any one of these functions results in a distorted cost picture.

What Truly Contributes to Landed Cost?

Landed cost is cumulative by nature. It builds as the product progresses through the supply chain.

Key contributors typically include:

Purchase price paid to the supplier

Inbound transportation costs, including primary freight, fuel surcharges, and accessorials

Handling and loading charges at origin and destination

Customs duties, taxes, and compliance costs (for cross-border logistics)

Insurance and risk coverage during transit

Warehousing and storage costs, including inbound handling and put-away

Inventory holding costs, driven by transit time and dwell

Documentation, brokerage, and administrative overhead

What makes landed cost complex is not the presence of these elements—but how they interact.

A lower unit price may require longer transit routes, increasing inventory holding costs. A cheaper carrier may increase damage rates or delays, leading to rework, stockouts, or expedited shipments downstream.

Evaluating these costs in isolation leads to false savings. Landed cost only becomes meaningful when assessed end to end, across time, volume, and operational risk.

You May Also Like to Read: What Are Logistics Hubs? Your Guide to Their Role, Benefits & Types

Why Landed Cost Matters in Supply Chain Decision-Making?

Most supply chains don’t fail because costs are unknown. They fail because costs are misattributed. When procurement optimizes only for unit price, logistics optimizes only for freight rates, and finance reviews costs after execution, no one owns total cost performance.

This leads to predictable failure modes:

Cheaper suppliers that increase working capital pressure

Lower freight rates that increase service failures

Cost-saving initiatives that improve one metric while damaging overall profitability

Landed cost reframes decision-making around total cost ownership. It forces trade-offs into the open and aligns decisions with long-term performance instead of short-term optics. Organizations that understand landed cost early can prevent inefficiencies before scale amplifies them.

You May Also Like to Read: What is Supplier Relationship Management (SRM)?

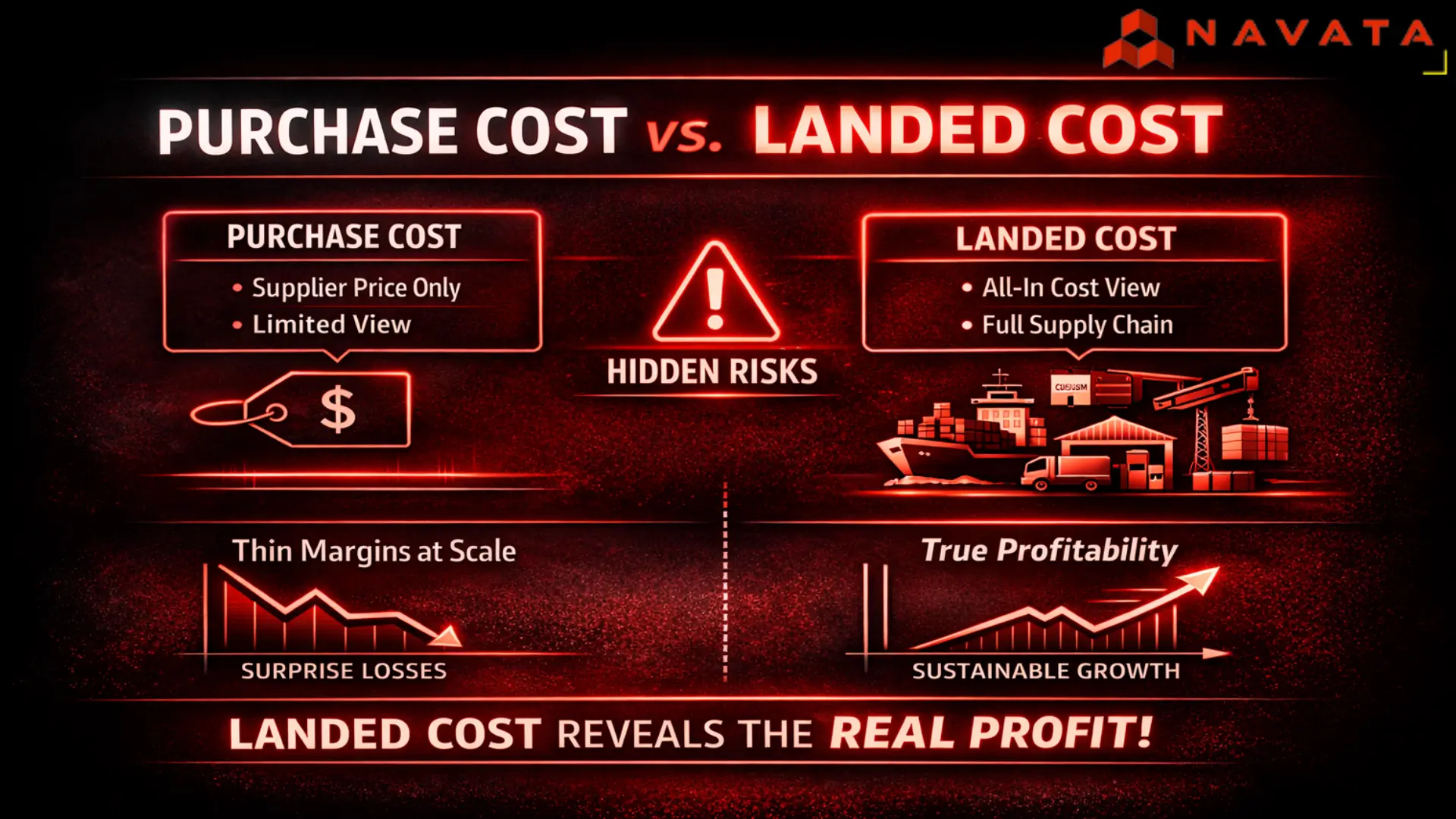

Landed Cost vs Purchase Cost: The Difference That Protects Margins

Purchase cost reflects what a supplier charges per unit. Landed cost reflects what that unit actually costs the business once it has passed through the supply chain.

This distinction becomes critical when setting prices or evaluating profitability. Pricing based solely on purchase cost assumes that logistics, inventory, and operational risks are either fixed or insignificant. In reality, these factors fluctuate and often represent a substantial portion of total cost.

When landed cost is ignored, margins appear healthy at low volumes but deteriorate as scale increases. Organizations that base pricing and commercial decisions on landed cost gain a far more accurate view of profitability and can grow without unpleasant financial surprises.

The Role of Landed Cost in Logistics Planning

In logistics planning, landed cost acts as a design lens rather than a retrospective calculation. Transportation routes, carrier selection, mode choices, and warehouse locations all influence how cost accumulates over the life of a shipment.

A longer transit route with lower freight rates may increase inventory holding costs and cash cycle time. A faster route may reduce operational risk and improve cash flow even if the upfront transportation cost is higher. Without landed cost visibility, these trade-offs are often judged subjectively rather than analytically.

Logistics teams that incorporate landed cost into planning are able to balance cost, service, and risk in a structured way, leading to more stable and predictable operations.

Common Mistakes Businesses Make with Landed Cost

One of the most common mistakes is treating landed cost as a static number calculated after goods have already moved. By that stage, the opportunity to influence decisions has passed.

Another frequent issue is failing to revisit landed cost as conditions change. Freight rates fluctuate, service performance varies, and operational inefficiencies emerge over time. When landed cost is not continuously reviewed, decisions that were once efficient slowly become sources of margin leakage.

These failures are rarely dramatic in isolation, but they compound quietly as the supply chain scales.

How Modern Supply Chains Control Landed Cost

Modern supply chains treat landed cost as a living metric embedded in daily operations. Instead of reviewing costs only after execution, they monitor how operational performance affects total cost in real time.

This approach changes the nature of decision-making. The question shifts from identifying the cheapest visible option to selecting the option that delivers the lowest total cost with acceptable service and risk over time. Organizations that make this shift gain tighter financial control and greater resilience in volatile operating environments.

Why Landed Cost Is a Strategic Metric?

Landed cost connects operational execution directly to financial outcomes. It exposes inefficiencies that individual teams cannot see in isolation and creates alignment across procurement, logistics, and finance.

More importantly, it reveals whether growth is genuinely profitable or merely increasing exposure to hidden costs. Businesses that understand landed cost gain clearer pricing control, stronger margins, and more predictable supply chain performance.

Read More About: What is Supply Chain Risk Management?

Conclusion

Landed cost is the most honest measure of supply chain economics. It reflects what products truly cost once transportation realities, operational complexity, and time-based expenses are fully accounted for.

In an environment of volatile freight markets and tight margins, managing landed cost effectively is not about cost reduction alone. It is about protecting profitability, enabling scale, and building a supply chain that performs consistently under pressure.

In modern supply chains, success is not defined by paying less at the start. It is defined by controlling the total cost from start to finish.

Thanks For Reading: What is Landed Cost in Supply Chain? A Real-World Explanation

Powered By 360Presence